Turning Yokohama into a craft beer city

When Shinya Suzuki founded Yokohama Bay Brewing in 2011, he set out to prove that Yokohama could be more than a port city with a brewing legacy. His ambition was to create a craft beer culture with global credibility.

DATE 2026-01-14More than a decade later, Yokohama Bay Brewing has become a familiar name in Japan’s craft beer scene, earning recognition at international competitions and helping shape the industry through events such as the Japan Brewers Cup, which Suzuki has hosted since 2013.

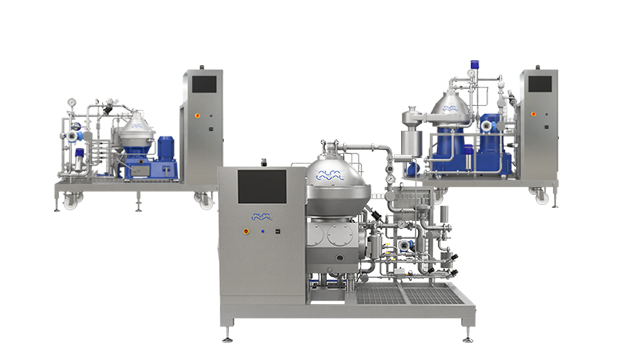

An important part of the brewery’s recent change comes from the centrifuge, a machine that never pours beer but plays a major role behind the scenes. In 2022, the company introduced Alfa Laval’s Brew 80, a compact centrifuge designed specifically for craft breweries. The adoption followed recommendations from other Japanese breweries and marked a turning point in Yokohama Bay Brewing’s production strategy.

The centrifuge immediately changed the workflow. Rapid clarification improved beer stability and raised overall quality. Filter clogging decreased because solids were removed more efficiently before filtration. With high separation efficiency, the Brew 80 reduced product loss that often occurs during gravity sedimentation. The tighter process also shortened production time and improved energy efficiency, cutting maturation from six weeks to four. Suzuki notes that filtration equipment became unnecessary after installation, removing an entire step from the process.

Shinya Suzuki at the World Beer Cup after winning the gold medal for Yokohama Bay Brewery’s Bay Pilsen

The shift was particularly significant for a brewery devoted to Czech style pilsners. Suzuki, inspired by Pilsner Urquell during study trips to the Czech Republic, has long focused on brewing Bohemian pilsners that balance tradition with modern technique.

Producing canned beer that stays stable at room temperature had been one of his persistent challenges. The centrifuge supported that goal by contributing to yeast reduction and minimizing oxygen uptake, thanks to its axial hermetic seal.

By introducing the centrifuge, filtration equipment became unnecessary, and the maturation period was shortened from six weeks to four. Production efficiency has increased.”

- Shinya Suzuki, Yokohama Bay Brewing

Even with these advantages, Suzuki operates cautiously to avoid making the beer lighter. This is because centrifuges make it possible to choose how much yeast and flavour active material remains in the beer, whether the goal is to brighten the flavour or to keep it closer to the original fermentation profile. “It is a product that can reliably improve product quality and shorten processes, transforming the craft beer production workflow”, says Suzuki.

Yokohama Bay Brewing’s pursuit of higher quality extends beyond domestic borders. The brewery continues to compete internationally, including at the World Beer Cup, where it has earned gold and silver medals.

At its Totsuka facility, additional Alfa Laval pumps have been installed to build a unified production system. The result is a brewery that pairs tradition with technology, using modern separation equipment.