Alfa Laval’s spiral heat exchangers deliver pioneering efficiency in renewable natural gas production

Advanced heat exchanger technology Alfa Laval’s spiral heat exchangers have delivered significant energy savings, increased uptime, and impressive ease of maintenance for US Energy at its Freedom facility, a renewable natural gas (RNG) production plant located at a dairy farm in Wisconsin.

DATE 2025-12-02

Innovative solutions for challenging conditions

Manure mixed with bedding is a feedstock with varying viscosity and can contain up to 10% solids. This poses significant challenges at Freedom RNG, but Alfa Laval’s spiral heat exchangers have shown their worth above other technologies in handling these tough conditions.

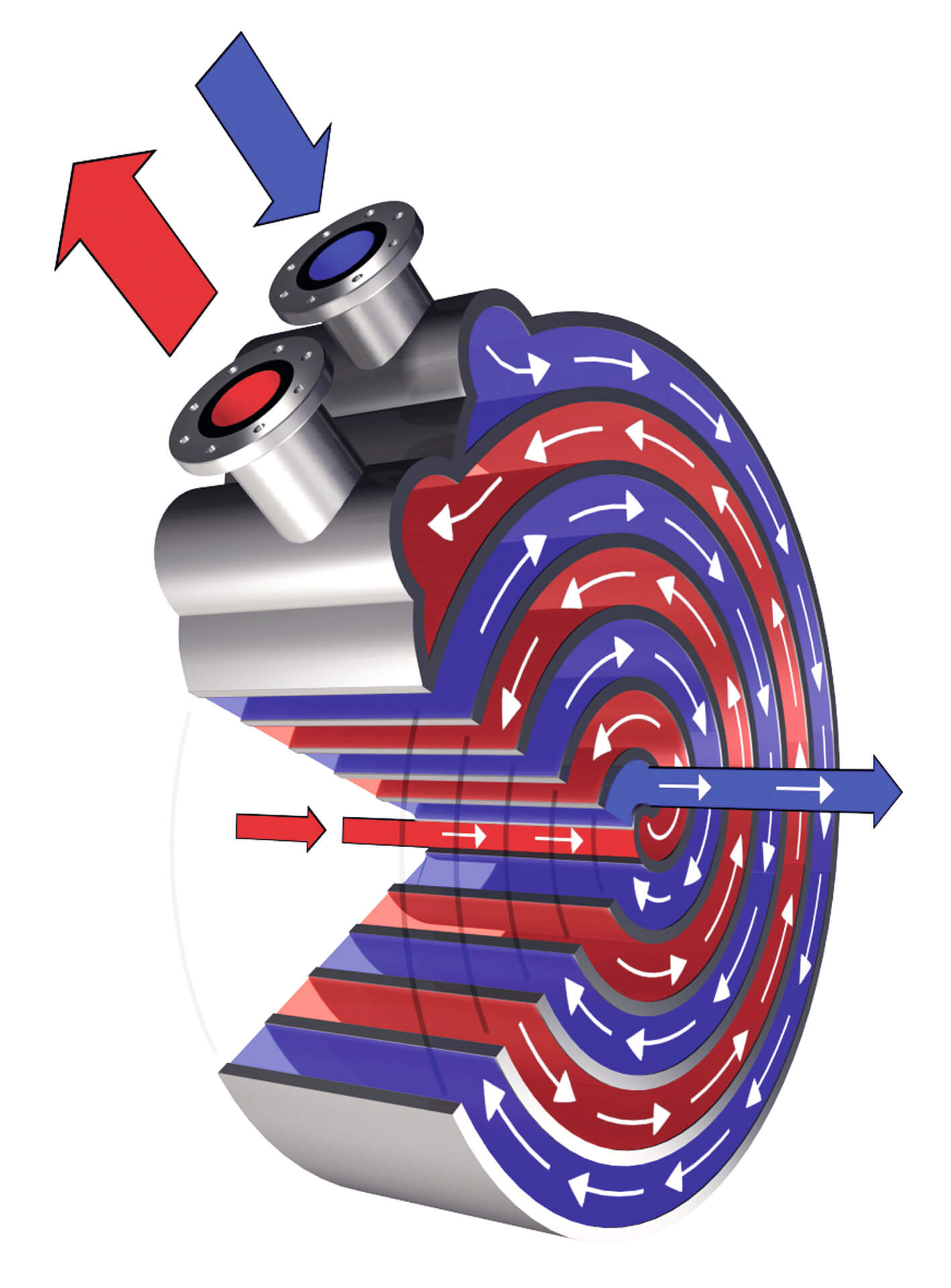

The piping both upstream and downstream of the heat exchangers has been subjected to clogging on different occasions due to the fibrous nature of the feedstock, but the spirals keep on performing. The continual curving, single-channel geometry creates high turbulence, minimizing fouling and clogging from the start. If fouling does occur, the self-clean design increases local velocity, creating a scrubbing effect that flushes away deposits.

“Since we started our trials, there has actually been no need for regular cleaning, which is a significant advantage over expectations,” says Kristopher Kreh. “We anticipated having to clean the exchangers every four to six weeks. However, after 18 months of continuous operation, the units have remained clog-free and have required no maintenance, aside from routine inspections confirming their clean condition.”

The dairy’s scraped output from the barn – animal bedding and manure – serves as feedstock for Freedom RNG, a new installation designed to produce 20,400 m3/day (720,000 STCF/day) of biomethane. The facility operates six Alfa Laval spiral heat exchangers that are delivering a robust technological solution in challenging conditions, and offering peace of mind to US Energy in its operations.

The reason for selecting spiral technology was its higher heat transfer efficiency, with the ease of maintenance being the icing on the cake.

Kristopher Kreh Director of engineering, US Energy

Real-world success

Freedom has taken significant steps to improve the efficiency of its RNG production by operating with a two-stage digester and increase the gas output. The two-stage digester consists of one stage at hyperthermophilic temperatures and the second at mesophilic, which means they first need to heat up the manure and then cool it down again. This is where Alfa Laval’s innovative and versatile spiral technology thrived.

Three of the heat exchangers run sludge-to-water to heat the manure to reach the hyperthermophilic temperature of 74°C (165°F). The other three operate sludge-to-sludge, recovering heat to the incoming sludge, while cooling down the digested sludge before it goes into the lower temperature mesophilic stage. At Freedom RNG, these sludge-to-sludge spirals serve up savings of 7,200 MWh/year (2 MMBTU/hr) and 87 tonnes of CO2 eq/year.

A bright outlook

“Our spiral heat exchangers have outperformed initial expecta[1]tions, proving to be a game-changer in the RNG industry. They allow the process to run smoothly and efficiently, which is exactly what facilities need as they expand. We’re really excited to see how this technology can help more sites surpass their goals,” says Kristopher Kreh.

By optimizing the conversion of waste to energy and ensuring minimal downtime and maintenance, Alfa Laval spiral heat exchangers are paving the way for a sustainable future, one facility at a time.

Highlighted Technologies

The sludge-to-sludge spiral technology is designed to handle sludge stream on both sides of the heat exchanger without the need for an intermediate water loop compared to conventional designs.

Key benefits

High heat transfer efficiency and significant energy savings: The sludge to sludge units recover 7,200 MWh/ year (2 MMBTU/hr), and 87 tonnes of CO2 eq/year.

Increased uptime: More than 18 months of continuous, reliable operation, without any need for maintenance. Self-clean design overrides the usual cleaning frequency of 4–6 weeks.

Ease of maintenance: Freedom RNG utilizes the flush ports to back flush when required prior to shutdown. Operators spend only 2–3 hours on maintenance thanks to easy access to both channels.