The food processing world is opening up for Hygienic WideGap

There are not many people better placed to judge the benefits of Alfa Laval’s Hygienic WideGap plate heat exchanger than an expert who has spent years designing process equipment with traditional tube technology.

DATE 2025-10-23

Magnus Wessman is perhaps uniquely placed in the drive to promote the Hygienic line ange in a sector where tubular heat exchangers have been the preeminent technology for around 30 years. With the food and beverage industries facing more stringent regulations on hygiene and safety, the WideGap is now coming into its own, although the journey of its development started almost a decade ago, and Magnus was part of the team behind its inception.

“We started trying out the industrial WideGap design in 2017 on hygienic applications, and it worked really well in principle,” he remembers. “The customer was happy with the results, but we knew it was not specifically designed for the job, so we set about refining the design for hygiene, improving the efficiency and ensuring good heat distribution across the plate, with no ‘dead zones’.”

That refining included smoothing out the crevices between the plates to ensure good flow, avoiding stagnation, and focusing on the port area where particles and fibres can get stuck. They were also designed to be configured with wide-wide or widenarrow channels, which make the plate flexible to handle different duties such as heating, cooling and heat recovery duties.

“Supported by our 30 years of experience in industrial WideGap technology we embarked upon a lot of dynamic simulation with different fluids, made a prototype and then tested that,” says Magnus. “We knew we were getting somewhere and had a really good plate”.

Now, in his expert opinion, there is only one winner in terms of cost, efficiency and sustainability, when it comes to processing viscous or fibrous fluids with a high level of hygiene required.

“I have a background in tube design, but the Hygienic WideGap heat exchanger really has changed the game when it comes to hygienic processing applications for processing fluids with high viscosity or fibres and larger particles,” he says.

“It is already blazing a trail in the market and has solved a lot of pain points for customers. It beats tubular technology on the key metrics. It is unique because it is specifically designed for hygienic applications as part of the Hygienic line, and there is no other product out there that can do what it does so effectively.”

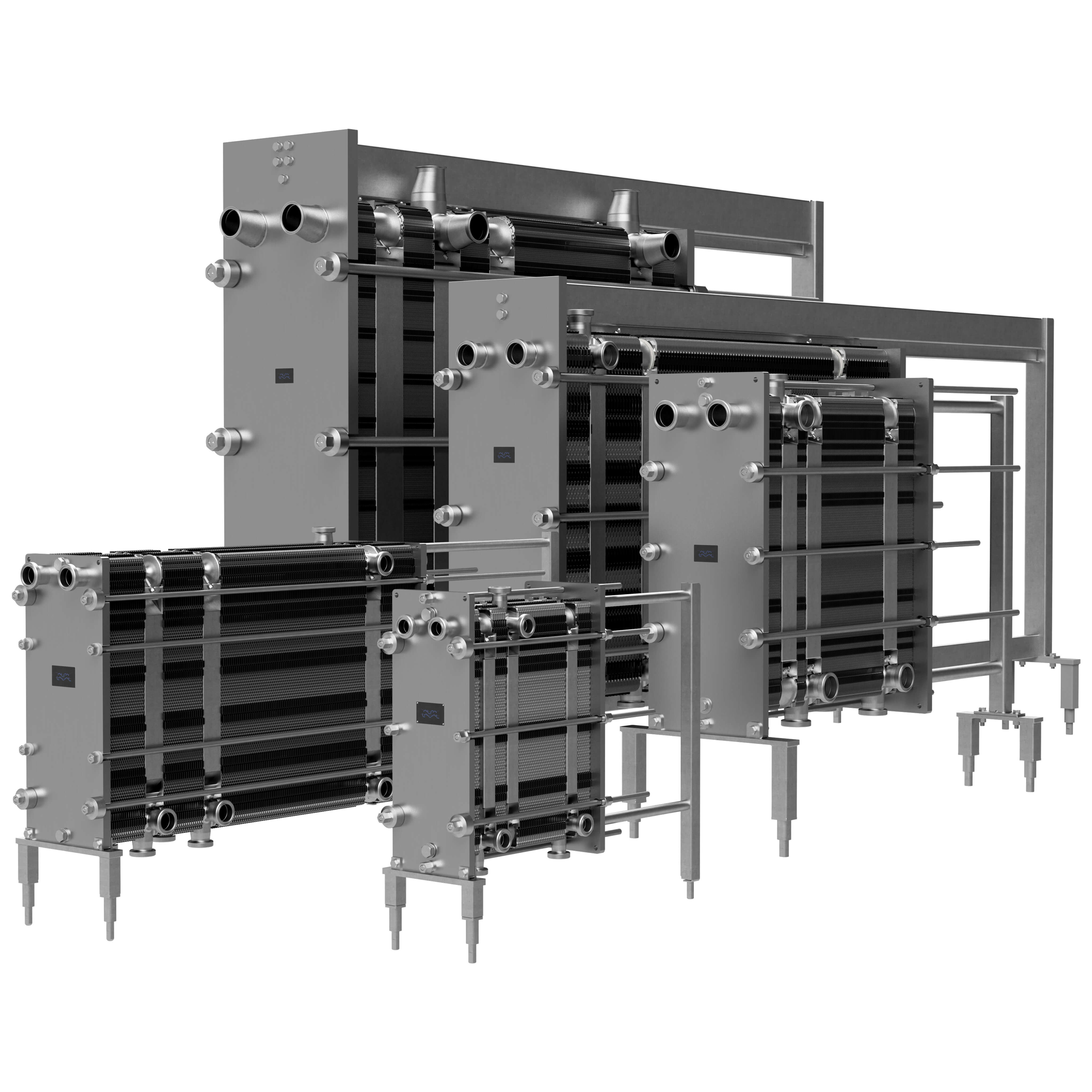

The higher thermal efficiency and better flow geometry of the Hygienic WideGap means the unit is more compact than its tubular counterparts, taking up as little as 20% of the floor space, and is about 80% lighter when filled with process liquids.

The improved thermal efficiency compared to shell and tube heat exchangers also mean improved heat recovery, and the WideGap plate delivers less of a pressure drop, resulting in energy savings. The counter-current flow, with the product on either side of the plate heating and cooling, also means it can heat the cold stream to a temperature very close to that of the entering hot stream.

Plate technology generates less resistance compared to tubular heat exchangers, meaning less pressure drop. On top of these benefits, the better flow minimizes the clogging and means cleaning sessions and downtime are reduced, with much less cleaning media required, and the flexibility of the system means that the plates can easily be reconfigured depending on the fluid to ensure maximum performance.

“The benefits are across the board, and the potential of this technology for our customers and for us is enormous,” says Magnus.

“We at Alfa Laval are determined to seize this moment because there is nothing out there like the Hygienic WideGap plate heat exchanger, and the impact it can have in terms of performance, sustainability, cleanability, and of course, cost, is huge.”

Highlighted Technologies

Hygienic WideGap

Increase your process hygiene and energy efficiency with our hygienic WideGap plate heat exchanger, part of Alfa Laval Hygienic line. Engineered specifically for fluids containing fibres and particles, this innovative technology enables impressive energy savings and heat recovery, surpassing the limitations of traditional shell and tube heat exchangers. Designed for food processing applications, the hygienic WideGap is perfect for a wide range of products, ranging from pulp-filled juices and purées to crushed tomatoes, dressings, and even plant-based beverages.

Magnus Wessman, Product Manager GPHE Hygienic, Food & Water Division

“We could do a lot of testing in real-life situations, so at customers’ sites trying different fluids and seeing where and how the various fibres or particles might get stuck, which meant we had a lot of information and evidence to help make the Hygienic WideGap the best it could possibly be.”