2018-12-03 Product news

Alfa Laval OF 900 separator maximizes separation performance and reduces the need for up- and downstream equipment

Specifically designed with the high standards and demands of the oil and gas industry in mind, Alfa Laval OF 900 is a compact centrifugal separator for separating solids – especially hazardous contaminants – from fluids, such as condensate, oil and/or water. It is ideal for tough separation cases where submicron particle contaminants (e.g. mercury and arsenic) need to be removed.

“We drew on our decades of oil and gas industry field experience – both on- and off-shore – while developing OF 900,” says Joakim Johansson, Global Sales Manager for disc stack centrifuge projects. “We know the hazardous contaminants these customers need to remove and have created a centrifugal separator that will provide them years of trouble-free uptime and high separation efficiency.”

Unique design features

Two elements set Alfa Laval OF 900 apart from other centrifugal separators: a center-to-center flow path and the Hermetic Design.

The center-to-center principle ensures gradual process liquid acceleration into the high G-force separation environment of the disc stacks. Thanks to the efficiency of this flow path design, Alfa Laval OF 900 uses 30% less power than conventional centrifugal separators,

When it comes to process integration, both the inlet and outlet of Alfa Laval OF 900 are hermetically sealed by mechanical seals – Hermetic Design – preventing gas flashing inside the separator and eliminating the need for upstream degassing vessels.

“These two features are what make Alfa Laval OF 900 the optimal choice for oil and gas process integration – every operation needs an efficient separation system that also saves energy and reduces risks,” remarks Joakim.

Standard design features

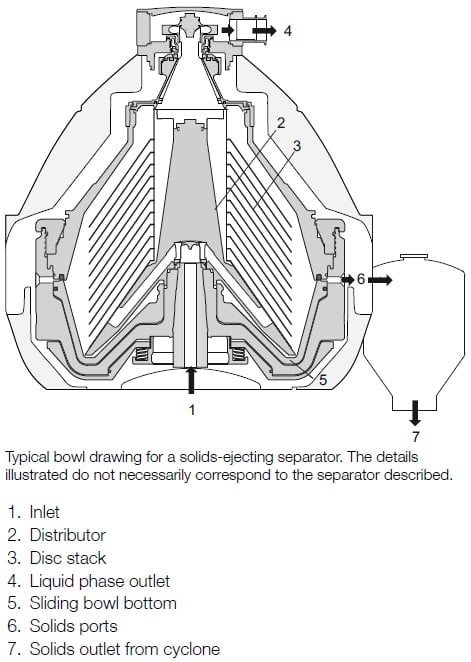

With regard to its overall design, Alfa Laval OF 900 is similar to other centrifugal separators, meaning it consists of a machine bottom part – housing a gear drive and lubrication system – and a top part – featuring the bowl, bowl casing with cooling jacket and outlets for separated liquids and discharged sludge.

To improve its long-term performance under all conditions, all of Alfa Laval OF 900 metallic parts – in contact with the process liquid – are produced from high-grade stainless steel. Equally robust are the gaskets and seals, which are made from Viton® (a brand of synthetic rubber and fluoropolymer elastomer).Together, these components ensure that Alfa Laval OF 900 provides an extra-long lifecycle with minimal maintenance requirements.

Straight-forward and thorough operation

The operation of Alfa Laval OF 900 is incredibly efficient. The process feed enters the centre of separator bowl from the bottom, via a hollow drive spindle, creating a liquid-filled, low-shear environment.

The process liquid flow gradually accelerates into the bowl, keeping feed droplets/particles intact. This facilitates superior separation performance and greater product integrity – critical when handling emulsions or shear-sensitive particles.

Separation takes place between the bowl discs where the liquid phase moves towards the centre of the bowl and the high G-forces force the solids toward the outside of the bowl.

These solids are collected in the periphery and intermittently discharged via the discharge ports as the sliding bowl bottom moves downwards. They eventually leave the separator by way of a sludge cyclone.

“The center-to-center flow of the OF 900 ensures that hazardous contaminants are extracted from condensate streams with high efficiency and no air entrainment,” explains Joakim.

Lastly, the freshly separated process liquid leaves the bowl through the hermetically sealed outlet in the top of the separator under pressure – created by an impeller – eliminating the need for downstream booster pumps, in most processes.

Small size makes a big difference

The center-to-center design with its short settling distances not only helps ensure a low hold-up volume, it also keeps the footprint of the centrifuge small – especially when compared to filter and coalescing systems. The Hermetic Design – completely encapsulating the process liquid – reduces the need for upstream degassing equipment, which also helps decrease space requirements.

“We’ve made Alfa Laval OF 900 easy and cost effective to integrate into any process,” comments Joakim. “This is particularly important when our customers are contemplating installing or replacing an existing filter system.”

Easier cleaning and handling

Another clear upside of Alfa Laval OF 900, and centrifugal separators as a whole, is its ease of cleaning and maintenance.

The separator intermittently discharges solids of variable volume, which then exit the separator via a sludge cyclone. Unlike cleaning a filter, separated deposits are easily removed and disposed with minimal mess and human contact with hazardous material.

Regarding maintenance, the disc stack of the OF 900 separator has been designed to be cleaned in place (CIP), further adding to the low total cost of ownership.

“Companies looking for superior separation performance for problem feeds with submicron particle contaminants, such as mercury and arsenic, should definitely consider Alfa Laval OF 900,” concludes Joakim.

To learn more about the Alfa Laval OF 900 and the complete range of centrifugal separators, visit www.alfalaval.com/of

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2017, posted annual sales of about SEK 35.3 billion (approx. 3.6 billion Euros). The company has about 16,400 employees.

Tags

All

For further information, please contact:

Joakim Johansson, M.Sc.

Global Sales Manager HSS Projects, Business Unit Energy Separation

Tel direct: +46 853 065 534 / Mobile: +46 733 995 534

joakim.johansson@alfalaval.com