2015-05-25 Product news

Launching new Alfa Laval TK20 semi-welded heat exchanger

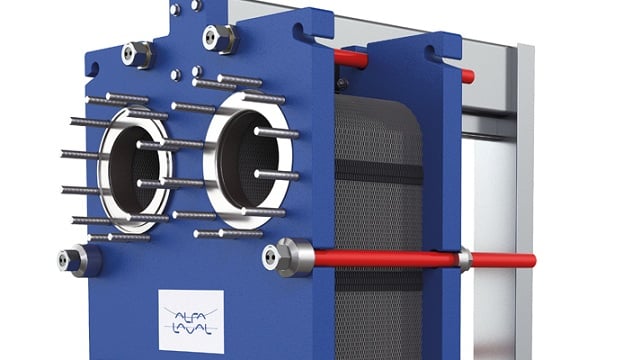

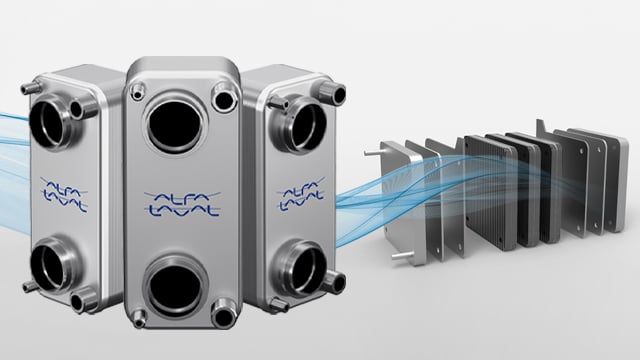

The new Alfa Laval TK20 semi-welded gasketed plate heat exchanger is optimized to deliver the best in performance and reliability for heating and cooling of aggressive media.

The TK20 is developed for all applications where high efficiency is key, such as evaporators, condensers, desuperheaters, cascade duties and economizers/subcoolers. It is optimized for the use of natural refrigerants, NH3 and CO2, for low and high pressures. The new plate design is especially suitable for flooded evaporation duties.

The heat exchanger features innovative new developments that include Alfa Laval RefTight™ – the unique gasket groove design with maximum gasket support and minimum gasket contact, Alfa Laval CurveFlow™ – patented distribution zone with more energy efficiency per m2 plate surface, and Alfa Laval ClipGrip™ – patented mounting method that attaches the gasket securely, gripping both sides of the plate, ensuring that it stays in place when opening.

The TK20’s compact design makes it easy to open for inspection and cleaning, which facilitates higher serviceability. Its flexible configuration allows the heat transfer area to be modified according to the user’s application and needs. The welded channels with minimum gasket contact also create a robust leakage-proof unit.

Benefits at a glance:

- Leakage-proof design of the welded channels

- Flexible configuration – heat transfer area can be modified

- Compact design

- High serviceability – possible to open the heat exchanger for inspection and cleaning

- Part of a large portfolio of heat transfer products

With the new TK20, the growing demands on energy efficiency, lower approach, low delta temperatures / high flows, and larger capacity range can now be fulfilled. The TK20 makes an excellent extension to Alfa Laval’s range of semi-welded gasketed plate heat exchangers.

About Alfa Laval:

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

For further information contact:

Jesper Olsen, Market Manager Industrial Refrigeration, Industrial Equipment Segment

Alfa Laval Lund AB, Lund, Sweden

+46 46 36 73 90

jesper.olsen@alfalaval.com

Klaudija Cavala, Central Market Communication Manager, Industrial Equipment Segment

Alfa Laval Lund AB, Lund, Sweden

+46 46 36 77 57

klaudija.cavala@alfalaval.com