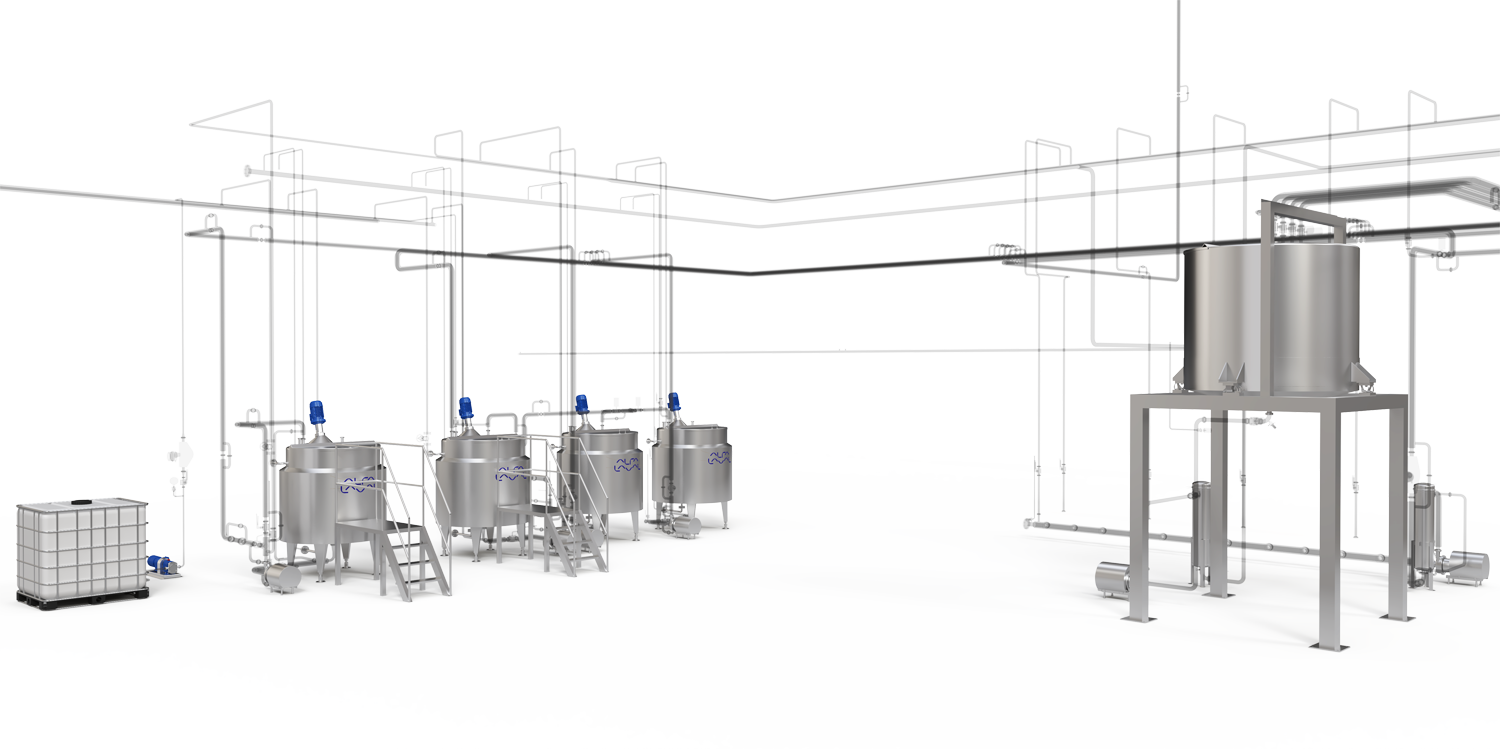

Margarine plant systems

Unlock revenue and maximize your edible oil investments with Alfa Laval. Transform oils into high-value spreads, margarines and shortenings, hard, liquid, cake, cream or puff pastry, by using our fully automated, hygienic, and modular margarine production lines. Achieve top performance, consistent quality and higher yields and expanding your product range to meeting market demands. Futureproofing your operations with Alfa Laval you easily scale your margarine plant as your business grows.

Flexible, highly efficient production line for high-quality margarines, shortenings and spreads

- Modular plant that easily adapts to capacity requirements

- Fully automatic, cost-effective skid-mounted processing systems

- Proven, hygienic product

- Highest product quality, optimized yield

- A single point of contact for all your margarine production processes

Producing high-quality margarine and shortenings takes more than just the right equipment. It requires a holistic approach and end-to-end insight into the manufacturing process. Every step matters – from sourcing fats, refined and possibly modified to fit the melting curve requirements, adding water and emulsifiers and managing melting points, pasteurization and crystallization. Achieving the right solid-liquid balance ensures smooth, stable products with optimal flavour, texture and nutritional value. Let Alfa Laval help you maximize yield, reduce costs, and boost profitability with flexible, hygienic production lines built to grow with your business.

Documents

Product leaflets

What is the margarine production process?

The margarine production process consists of five key steps: preparing the oil phase with emulsifier, handling the water phase, creating the emulsion, pasteurizing the mix, and crystallizing the final product. If the target product is shortening, there will not be addition of a water phase. Together, these steps ensure consistency and high product quality. Any excess product is efficiently reprocessed through a continuous rework unit that returns it to the emulsion tank for efficient reuse.

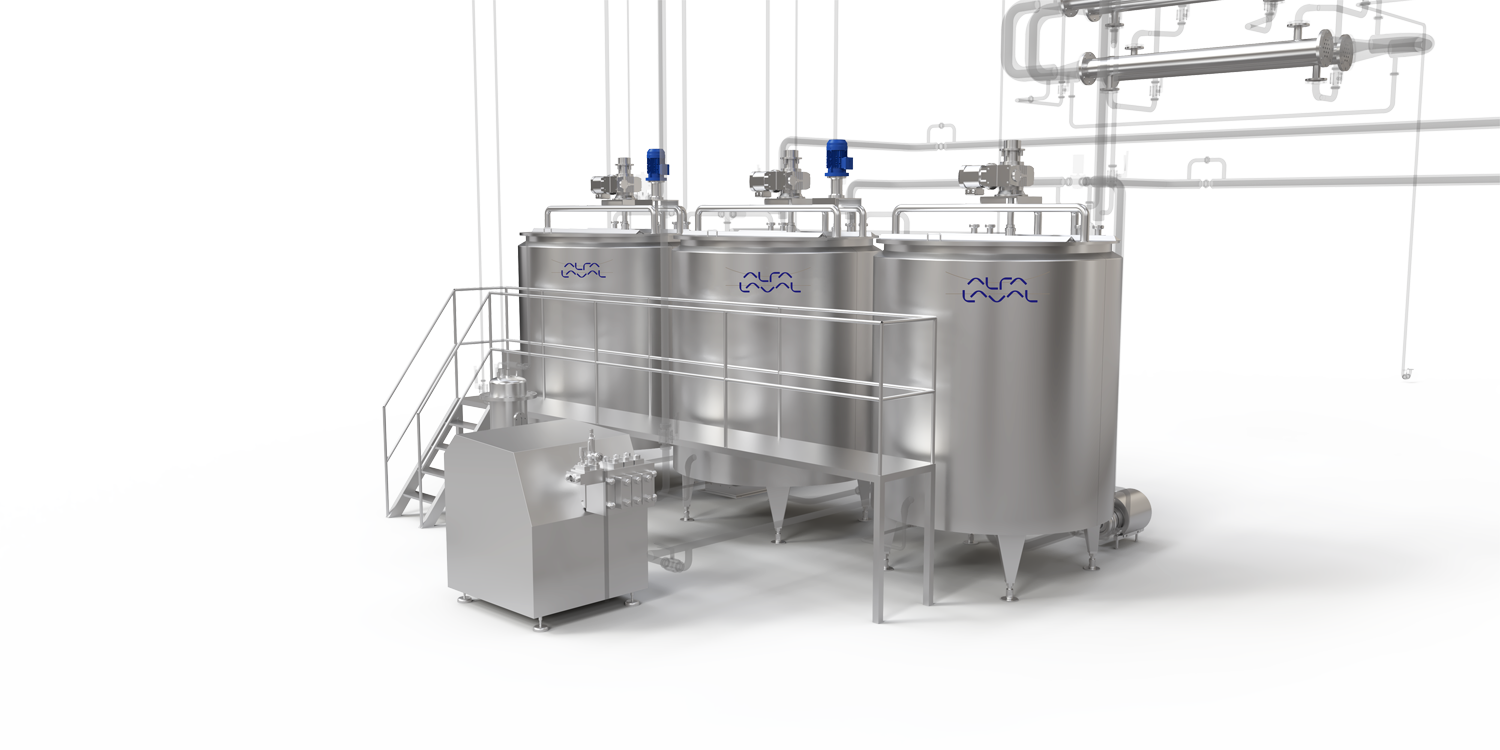

Oil phase and emulsifier prep in margarine production line

A pump transfers oil, fat or blended oil from storage tanks through a filter to a weighting system. To obtain the correct oil weight, this tank is installed above load cells. The blend oil is mixed according to a recipe.

Emulsifier preparation is accomplished by mixing oil with the emulsifier. Once the oil reaches a temperature of approximately 70°C, the emulsifiers such as lecithin, monoglycerides and diglycerides, usually in powdered form, are manually added into the emulsifier tank. Other oil-soluble ingredients, such as colouring and flavouring, can be added. If shortening is the final product, the oil phase goes directly to crystallization. For margarine, a water phase is prepared, mixed with the oil phase, and pasteurized before entering the crystallization stage.

Water phase process in margarine production

Insulated tanks are supplied for the water phase. A flow meter doses the water into the tank where it is heated to a temperature above 45ºC. Dry ingredients such as salt, citric acid, hydrocolloids or skimmed milk powder may be added into the tank using special equipment such as a powder funnel mixer.

Emulsion stage in margarine production

The emulsion is prepared by dosing oils and fats with the emulsifier blend and the water phase in the said order. Mixing of the oil phase and water phase takes place in the tank. Other ingredients, such as flavouring, aroma and colouring, may be added manually. A pump transfers the resulting emulsion to the feed tank.

To ensure optimal contact between the oil phase and the water phase, special equipment, such as a high shear mixer, may be used to achieve a very fine, homogeneous and stable emulsion. The resulting emulsion will produce a high-quality margarine with excellent plasticity, consistency and structure.

A pump then forwards the emulsion to the pasteurization area.

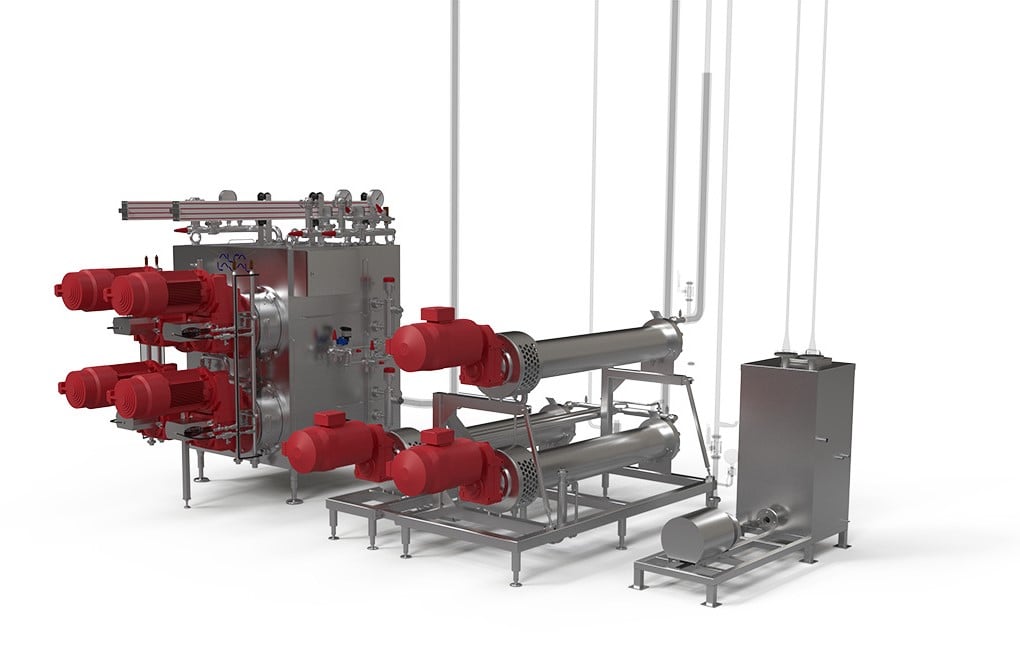

Pasteurization stage in margarine production process

A skid-mounted pasteurization unit handles in-line pasteurization. A pump transfers the emulsion through a wire mesh filter to a plate heat exchanger for pasteurization. Another pump facilitates the circulation of hot water through the plate heat exchanger. Pasteurization occurs at temperatures between 80°C and 85°C; the process takes several seconds. Heating the emulsion inhibits the growth of bacteria and other micro-organisms and improves the stability of the emulsion before leaving the pasteurizer at a temperature of between 45°C and 50ºC.

Crystallization stage in the margarine manufacturing process

A high-pressure pump transfers the emulsion to a high-pressure scraped surface heat exchanger (SSHE). The SSHE is configured according to the flow rate and recipe using cooling tubes of various sizes and surfaces. Each cylinder has an independent cooling system into which the refrigerant, typically ammonia R717, is directly injected. Product pipes connect each cylinder to one another. Temperature sensors at each outlet ensure proper cooling. The maximum pressure rating is 120 bar.

Depending on the recipe and application, the emulsion may pass through one or more pin worker units to achieve the right product plasticity, consistency and structure before packing. If required, Alfa Laval can supply a resting tube; however, most packing machine suppliers provide one.

Continuous rework unit in the margarine plant

A continuous rework unit is essential in any modern margarine plant. It is designed to re-melt any excess product that by-passes the packing machine for reprocessing. At the same time, it keeps the packing machine free of any undesired backpressure. To ensure energy efficiency and product quality, the unit typically includes a plate heat exchanger, a tempered recirculating water pump, and a water heater.

A unique partnership

Alfa Laval has partnered with RONO, specialists in process solutions for the food industry, to deliver fully integrated, customized margarine process systems for your plant. Together, we offer complementary solutions that meet your needs. We design and deliver solutions tailored to your specifications and desired end product, whether upstream refining and fat modification sections or highly flexible, multifunctional systems. Stronger together, Alfa Laval and RONO bring you unmatched expertise in margarine plant system design, engineering, service and support, backed by our combined global presence.

Optimizing the edible oil process

Turning crude oil into high-quality edible oil demands both expertise and precision. Alfa Laval brings extensive process knowledge across every refining stage – from degumming, neutralization, dewaxing, fat modification, bleaching, deodorization to GE and 3-MCPD mitigation. Our proven technologies ensure consistent quality, improved yields and greater efficiency while meeting food safety and sustainability requirements.

You might also be interested in ...

Q&As about the Alfa Laval Margarine Plant Systems

About Alfa Laval, Rono and the Margarine Plant Systems

Are there standard capacities for the Alfa Laval Margarine Plant Systems available for shortening? For margarine? No, there are no standard capacities because our systems are always tailored to customer requirements.

Most margarine plants typically share the same location as oil refineries that have hydrogen facilities. Can you build a margarine plant as an independent production facility? If so, what factors should be taken into consideration? Yes, a margarine plant can operate independently with its own dedicated tank farm. It does not need to be connected to an edible oil refinery.

What is the relationship between production capacity and cooling capacity? There is no fixed relationship. Factors such as the recipe, oil ingredients, and product type affect production and cooling capacity.

About margarine, shortening, and recipes

What is anhydrous margarine? Anhydrous means ‘containing no water’. Anhydrous margarine is therefore a vegetable fat compound, similar to shortening, with minimal water content.

Can you use the same process and equipment to produce a margarine containing 20% fat as you do for shortening? No, we do not recommend using the same equipment to prepare a margarine emulsion and shortening.

Are there any special considerations for producing soft, low-calorie, high-water-content margarines (halvarines)? For low-fat and half-calorie margarine, or halvarines, it is essential to create a stable emulsion from the start and to ensure the emulsion tanks are properly designed. Water quality is also important, as is pasteurization.

How do fractionated oil components affect product behaviour? It depends on the recipe. Fractionated oils are essential for achieving high-quality products, but can impact product behaviour in different ways.

About the water and oil phase

To produce a good mixture of water and oil in margarine, what is the ideal percentage for the emulsifier? There is no golden rule, as the percentage largely depends on the ingredients. As a guideline, the percentage may range between 0.3-0.6 %.

How do you reduce shrinkage in puff pastry? To ensure the product has better plasticity, you can reduce the lecithin dosage in the recipe by 0.1-0.2 %.

What should be the quality parameter of feed oil for margarine? The oil feed must be refined oil with a maximum free fatty acid content of 0.05 % and no peroxides.

Can product throughput be improved by using non-hydrogenated oil? Yes. Palm stearin and hard stearin with iodine values of 12-13 can improve throughput instead of using hydrogenated oil.

Which chemical is best suited for emulsified butter? Monoglycerides are effective for producing emulsified butter.

How does the oil blend affect ‘oiling out’ during margarine storage? Ensuring a stable emulsion and proper crystallization helps prevent oiling out. Storage temperature and time also affect oiling out, as do the recipe and the processing parameters.

How can you prevent post-hardening of palm oil products – especially fat used for filling applications? The recipe is key in preventing post-hardening of palm oil products. Preparing a good emulsion and using lecithin also helps minimize post-hardening.

About mixing, blending and dosing

Can you improve the thickening process, or emulsification, by using a high shear mixer? Yes, a high shear mixer or agitator can minimize the size of the water droplets, which helps increase plasticity and improve thickening.

What is the recommended agitator speed for mixing the oil and water phases? The recommended agitator speed depends on factors such as tank shape, tank dimension, and agitator type. In general, 30 rpm and 70 rpm are the recommended speeds.

How do you improve plasticity in margarine? Using a high shear mixer helps improve plasticity.

Is there a high shear mixer in the water phase mixing system? No, there is no need to use a high shear mixer in the water phase. However, we recommended it for the emulsion phase.

Can you use a high shear mixer to produce pourable shortening? We do not recommend using a high shear mixer to produce pourable shortening.

Can a palm-based oil blend reduce post-hardening issues in margarine? Yes, using a palm-based oil blend, a tank above load cells, and a tank with an agitator helps minimize post-hardening issues.

About crystallization

How do you determine when to use a crystallizer (SSHE) and a pin worker? It depends on the product, recipes, and types of filling and packing systems. Products that are filled smoothly require less cooling and more treatment to ensure the proper crystallization structure. Additionally, the selection of the SSHE and pin worker type and size depend on the production capacity.

What are the differences between a pin worker unit and a plasticator? A pin worker unit and a plasticator differ in size or volume. Pin workers are typically positioned at the crystallizer, handle larger volumes (25–180 litres), and run at lower speeds. A plasticator is positioned in front of the filling machine, handles smaller volumes (25-50 litres), and runs at higher speeds.

Please specify the parameters to keep in mind when using a pin worker unit to achieve the best plasticity for margarine? Volume and the shaft speed are primary parameters to keep in mind when using a pin worker unit to achieve optimal plasticity. Volume defines the resting time through the pin worker unit, and speed determines the treatment intensity. To ensure the product is not overworked, both parameters must be adapted to achieve the right texture for a specific product.

Can using the new high-pressure crystallization system prevent the maturation process of liquid shortening? No, the crystallization system does not affect the maturation process of liquid shortening.

How can we reduce shrinkage in puff pastry margarine? Puff pastry products require long crystallization times. Large cooling surfaces, an intermediate pin worker unit, large volumes of resting tubes, and the right process temperature profile contribute to minimizing shrinkage.

What is the maximum rpm of a plasticator? 1200 rpm.

What is the ideal rpm for a pin worker unit? Typically, it is approximately 200-350 rpm, depending on the product and recipe.

What is the difference between a standard pin worker unit and a pin worker unit used for shortenings? The only difference is the duration of treatment time. Margarine requires about one minute, while shortening requires approximately 2.5 minutes.

About pasteurization and preservation

Why use a small plasticator with 850-900 rpm? It provides intensive treatment, typically in 15–20 seconds, to achieve a proper crystallization and smooth texture of margarine and edible fat products before filling. Sizes and shaft speed always vary, depending on the end product.

What is the ideal temperature for the pasteurization process? How long is the contact at that temperature? The ideal pasteurization temperature is 85°C for about 17 seconds.

What is the most suitable heat exchanger for pasteurization? It depends on product viscosity or protein content. In most cases, Alfa Laval recommends scraped surface heat exchangers for pasteurization.

How do you prevent bacteria and fungi when producing salt-free margarine? Use preservatives such as citric acid, potassium sorbate or tartaric acid.

What is the ideal storage temperature and typical shelf life for margarine at that temperature? The ideal storage temperature depends on the recipe and end consumer. Industrial margarine can be stored at 16°C. Most recipes call for a storage temperature of 10°C, while the ideal storage temperature for table margarine is 4°C. Shelf life depends on the recipe but typically ranges from two to 12 months with proper cooling.

What is the recommended cooling surface for 3,000 kg/h production of margarine containing 15% water? Around 1.5 – 2 square metres, depending on the packaging.

Is it possible to add an FDA-approved preservative to prevent microbial growth in margarine with containing 18% water? Yes, preservatives approved by the US Food & Drug Administration prevent microbial growth and include citric acid, brine, tartaric acid, and potassium sorbate.

Is it possible to produce margarine with a water content of 18% without using a preservative? If so, how long we can keep this product at ambient room temperature? Yes, it is possible produce margarine with a water content of 18% without using a preservative, but only if:

- the quality of the water is sufficiently high

- no proteins are used

- the emulsion is pasteurized

- a proper cooling chain is maintained before delivery to the end user

Depending on the ambient temperature, shelf life is two to three months. With proper cooling, it can be extended to six to 12 months.

What is the main cause of margarine discolouration when properly stored? Discolouration when properly stored can result from exposure to bacteria or enzymes. Oil quality and fresh oil free from peroxide help ensure good margarine quality.

About Alfa Laval Contherm

Do I still need to use the Alfa Laval Contherm if I use the RONO scraped surface heat exchanger (SSHE) to produce shortening? Is the Contherm similar to the RONO SSHE? No. There is no need to use the Contherm together with the RONO SSHE. However, using the Contherm can improve plant capacity. While similar in design, the SSHE runs more efficiently at low pressure.

What is the annular gap for the SSHE? There are various annular gaps available, depending on the product and customer requirements. The standard annular gap is 10-11mm; however, 5-mm, 7-mm, 9-mm, and 15-mm gaps are available.

What is the refrigerant temperature used in Contherm? It depends on the media used. For glycol water, the temperature is approximately -5°C and, for ammonia, -28°C.

Why is Contherm used for precooling before crystallization? It is a low-pressure scraped-surface heat exchanger that cools the product to the desired temperature before it enters the high-pressure section.

Does Contherm improve the crystallization of palm fraction-based margarine and shortening? Yes, using Contherm before cooling palm fraction-based margarine and shortening improves product quality.

About heat exchangers in margarine processing

Can the scraped surface heat exchanger run continuously during palm kernel stearin production or cocoa butter substitute (CBS) production? Yes. With a higher scraping rate, the SSHE can run continuously. Adjusting the stearin or CBS melting point also prevents crystals from adhering to the shaft.

What is the optimal inlet temperature for the SSHE? About 45°C.

What type of heat exchanger should be used with ammonia or CO2? Ammonia remains the industry standard as a heat exchanger refrigerant. Depending on local conditions, such as temperature and the availability of refrigeration services, the CO2 cooling may be considered as an alternative. In both cases scraped surface heat exchangers are used. If the heat exchanger is provided with a drop tank, restarting will be fast and easy.

What heating systems do you recommend for restarting an entire plant in the event of a breakdown? For media with high melting points, any downtime may result in a system-wide shock. Recommendations for such heating systems depends on the type of equipment that breaks down. Mixing tanks are generally heated by a jacket surrounding the vessel while pipes are heated by double jackets using hot water. The scraped surface heat exchanger is heated using a hot water pipe inside the shaft.

About reworking

How much product can be reworked? Excess or surplus product, typically about 3-5%, from the packing lines is continuously recirculated to the mixing tank as rework product. In the event of packing machine downtime, the rework capacity is 100%. This enables all excess product to be remelted in a continuous rework unit and recirculated to the preparation tanks.

About cleaning and maintenance

How often should Cleaning-in-Place take place? Cleaning-in-Place should be scheduled at least once a week; however, the frequency of CIP depends largely upon the recipe and production sequence.

How do you prevent rust in the water phase tank and pipes? Using high-quality water with low hardness levels and thorough cleaning-in-place helps prevent rust formation.

Does standard insulation work for process tanks? Hygienic process tanks generally are stainless steel vessels with AISI 304 jacket and insulation (not cladding).

What type of pump is used to process liquid margarine containing 40% water? The pump type varies, depending on the processing stage. In the preparation stage, rotary lobe pumps are generally used. In the high-pressure section, circumferential piston pumps are the pump of choice.

Everything you need for outstanding margarines and spreads

Looking to build a new processing plant or scale up production? Optimize your margarine plant with Alfa Laval. With its broad knowledge and comprehensive solutions and equipment portfolio, Alfa Laval has global reach and local presence to meet your needs.

Webinars for the Edible Oil industry

Our experts share know-how to optimize edible oil refining processes, remove impurities and volatile components for better product quality, safety and yield.