Sustainable city: Alfa Laval plate heat exchangers repurpose waste heat from large cooling network into district heating

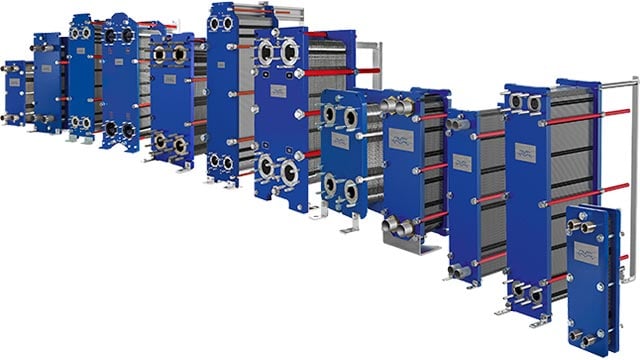

In the Berlin-based Qwark³ project, the potential of industrial high-temperature heat pumps to contribute to climate-friendly district heating is being demonstrated. A key factor for success is the use of compact, high-performance plate heat exchangers from Alfa Laval. These replace bulky shell-and-tube heat exchangers and enable maximum efficiency in limited space – a crucial element for successful sector coupling and the reduction of CO2 emissions on an urban scale.

DATE 2026-01-07Pioneering sector coupling saves 6,500 tons of CO2 per year

Since 1997, more than 12,000 offices, 1,000 apartments, as well as numerous cultural institutions and hotels around Potsdamer Platz are connected to the cooling network of BEW Berliner Energie und Wärme GmbH (formerly Vattenfall Wärme Berlin) and supplied with locally generated cooling. The amount of waste heat generated in the process is considerable – and far too valuable to be released into the environment via cooling towers.

In 2018, BEW and Siemens Energy therefore launched the ambitious Qwark³ (Quartiers-Wärme-Kraft-Kälte-Kopplung) project at the cooling centre at Potsdamer Platz. With the help of an industrial high-temperature heat pump, the waste heat from the cooling network would be used on a large scale for district heating. An important step to secure the future energy supply, on the path to a net-zero district. Brazed and semi-welded plate heat exchangers from Alfa Laval play a key role in this.

Maximum heat transfer efficiency in a small space

The major challenge at the beginning of the ambitious planning process – apart from the required heat transfer capacity – was the limited available space in the existing plant. With an installed cooling capacity of 45 megawatts (MW), absorption and compression cooling systems cool the district cooling water to 6°C – around the clock, 365 days a year. To make the most of the waste heat, the large heat pump had to be assembled from compact core components with high efficiency. Siemens Energy, paid particular attention to the compressor, as well as the selection of plate heat exchangers.

“We have worked with Alfa Laval in the field of energy transfer for a long time and sought contact early on to jointly find a customized solution for the Qwark³ pilot project,” says Thorsten Fippel, project manager at Siemens Energy.

Due to the spatial conditions and process engineering constraints, shell-and-tube heat exchangers were not an option. It quickly became clear that we would go for compact Alfa Laval plate heat exchangers, which have only one-third of the construction volume and are also easier to install because of their lower weight.

No compromises in terms of safety and performance

The compact design of the plate heat exchangers also means that their refrigerant charge is around 80 percent lower than other technologies. This not only minimizes the hazards posed by a non-flammable and non-toxic safety refrigerant such as R1233zd(E) used in Berlin. It also brings significant cost advantages in procurement and operation.

For evaporation, the project partners chose a semi-welded plate heat exchanger MA30W from the Alfa Laval Industrial Line. It allows a small temperature approach between the refrigerant and the heat source – a prerequisite for achieving a high COP. In addition, the model showed impressively low operating costs, thanks to its high energy efficiency and extended maintenance intervals. For condensation and subcooling, four brazed plate heat exchangers Alfa Laval CBH410 were installed in the large heat pump. These heat exchangers are available in the high-pressure version up to 28 bar. Because of their gasket-free design, the brazed units are maintenance-free, and particularly reliable and durable in high-temperature applications.

In the design, we worked closely with the Alfa Laval team and were able to rely on their enormous heat transfer expertise and practical experience at all times, Now we can look to the future with confidence. The Alfa Laval plate heat exchangers have low maintenance and service requirements thanks to their well-thought-out design. And our district heating network is becoming more independent of rising gas and CO2 prices.

recalls Ersan Topcu, who is responsible for the project at BEW.

A neighbourhood on the way to net-zero

Since the successful commissioning of the high-temperature heat pump in 2024, the Alfa Laval plate heat exchangers are converting the waste heat from the cooling centre at Potsdamer Platz into climate-friendly district heating – around 55 GWh per year with a maximum thermal heating capacity of 9 MW. This is fed directly into the district heating network, supplying 30,000 households with hot water in summer and heating 3,000 apartments in winter. The supply temperatures are between 85°C and 117°C, depending on demand.

All the electricity required for the compression of the refrigerant comes from renewable sources. Qwark³ is thus one of the first projects in which an industrial high-temperature heat pump makes waste heat usable on a large scale for a district heating system. The heat pump absorbs waste heat that would otherwise be dissipated by the recooling systems, thereby saving energy. It reduces heat dissipation to the environment by an estimated 36 GWh per year – almost half of the previous amount of waste heat. This amounts to annual savings of 6,500 tons of CO2 emissions, while the freshwater requirement of the cooling towers is reduced by 120,000 cubic meters. The pilot project has not only intelligently linked cooling and heating but also raised the overall efficiency of the system to a new level with its customized technology selection.

Download case story

Plate heat exchangers (PHE) in combined heat and power and cooling

- Compact design: With identical heat transfer capacity, an Alfa Laval PHE requires only one-third of the space of, for example, a shell-and-tube heat exchanger.

- Impressive efficiency: Optimized plate design ensures maximum thermal efficiency.

- Good for the environment and the cost balance: The required refrigerant charge is up to 80 percent lower.

>> More details about the project (German): Fernwärmeerzeugung aus der Abwärme einer Kälteerzeugung