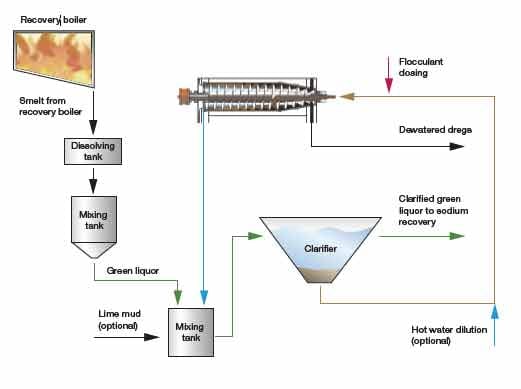

Green liquor treatment

Green liquor handling acts as the kidney of the pulp mill removing the non-process elements. At the same time, it ensures process chemicals can be recovered and reused time and time again.

Efficient and continuous separation

- Minimum solid waste to landfill

- No need for pre-coating with lime mud

- High chemical recovery

- Compact design and small footprint

- Low energy consumption and maintenance costs

Alfa Laval P2 solid bowl decanter centrifuges are a proven, effective solution for dewatering green liquor dregs in pulp mills. Compared to traditional rotary vacuum drum filters, Alfa Laval’s technology offers a highly efficient recovery of chemicals while minimizing the amount of dry cake and, thus, landfill/disposal costs.

Process overview

The smelt from the recovery boiler is mixed with weak wash and forms green liquor, containing mainly sodium carbonate and sodium sulphide. Before being causticized, impurities in the green liquor are removed in a clarifier tank. The dregs from the tank are dewatered continuously (no lime mud pre-coating required) in the decanter centrifuge before being sent for disposal.

How the P2 decanter works

Alfa Laval P2 decanter centrifuges separate green liquor from the dregs into a liquid and solid phase. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed slurry enters into the bowl through a stationary inlet tube and is then smoothly accelerated in the feed zone. Centrifugal forces of up to 3,500 G separate the solid particles from the liquid with the solids accumulating on the inner surface of the bowl.

The conveyor rotates in the same direction as the bowl but at a different speed. This gives an axial thrust to the solid particles and those particles tare then conveyed towards the conical end of the bowl. The solids leave the bowl through the solids discharge openings into the casing, while the clarified liquid leaves the bowl by flowing over adjustable plate dams or power tubes into the casing.

Case stories

Green liquor dregs dewatering

Södra Cell is one of the world’s leading manufacturers of market pulp. Learn how they reduced chemical losses in green liquor dregs with an Alfa Laval decanter centrifuge.

How can we help you?

If you have any questions about Alfa Laval’s solutions to sustainably optimize green liquor dregs handling or other vital pulp mill processes, get in touch with us now.