Mineral exploration drilling

In core (diamond) drilling, clean water is needed to drill the cores out. But when the water comes back from the hole it is full of drill cuttings and, in some cases, needs to be treated to minimize the environmental impact. That's where our decanter centrifuge is the best compact, high-capacity solution. It treats the waste, making it easy to transport away, while also cleaning the drill fluid. And, if water is limited at your drilling site, the decanter enables a closed loop water system.

High capacity with a small footprint

- Compact size for easy transport, faster installation, and less footprint on site

- Robust design for higher process efficiency and a longer product lifecycle

- High quality separation for better solids control and water reuse

- Stay ahead of important new sustainability regulations

- Plug and play design for easy and instant use

In recent years demand for treatment units has been driven by local waste regulations. But with an Alfa Laval decanter in your operation, major water savings are also possible. The small size of our decanters even makes it possible to install on a skid or in a container. With the right system design, you can just plug-in and start your operation, minimizing set-up time, avoiding digging pits in any weather or location, and keeping your operation running around the clock with simple daily system checks.

Savings in time, money and water use

All drilling contractors want high productivity with energy efficient, safe, sustainable, and ergonomic operation. With stricter regulations coming for waste handling and water use, a proactive approach is needed. With an Alfa Laval decanter centrifuge on site this is possible. A decanter centrifuge has a safe and environmentally friendly setup that gives savings in time, money, and water use. Download the story today to lean more!

Case story: compact and user-friendly waste and water treatment in mineral exploration

Watch the movie to discover how our decanter centrifuge is used for wastewater treatment at a mineral exploration drilling site in Sweden.

Waste and water treatment options in core (diamond) drilling

Important aspects to consider when choosing your waste treatment solution:

- Waste regulations

- Water use regulations

- Water availability

- Climate / conditions

- Footprint / landscape

- Access / transport

- Drilling fluid use

Site set-up without mechanized waste treatment unit, using traditional pits

In mineral exploration projects that use core drilling, clean water is needed. But, when the water comes back from the drilling hole it is full of cuttings and, in some cases, needs to be treated to minimize the environmental impact. This is especially the case in countries where stricter demands for waste disposal are being introduced. You could treat this waste using sedimentation tanks or pits (as shown in the picture) that separate the slurry from your wastewater. But these options take up more space, take a long time to set up, and involve manpower for maintenance during operation. So, in remote areas where being able to transport as little as possible is a high priority, this can be an issue.

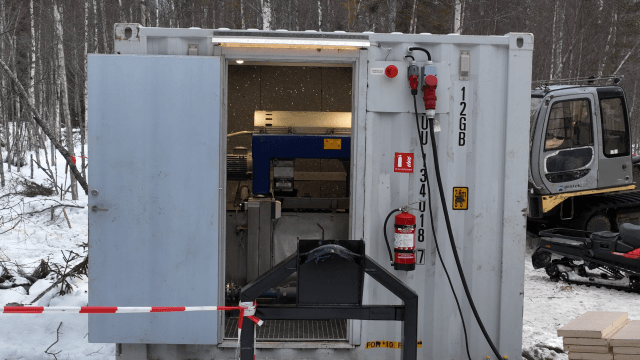

Site set-up with decanter centrifuge waste treatment unit

Another option for treating the waste is with a decanter centrifuge. The Alfa Laval Lynx 20 decanter centrifuge has a high capacity with a small footprint and can easily fit into a 10 ft container if needed. This makes it easy to transport and fit at most sites. The unit is also plug-and-play, so you can minimize the time spent setting up on the site with several sedimentation tanks or digging large pits. It is even easy to set up in more difficult conditions, like in a cold climate, remote area, or in an extreme landscape. The decanter centrifuge dewaters the waste, making it easy to transport and possible to circulate fresh water back to the drill-rig. This closed-loop system is perfect in locations where water is scarce or hard to access. The decanter is fully covered with no rotating parts exposed, making it both easy to install in a compact area and safe for the people on site. It is designed for 24/7 operations and, with a daily check, can easily operate for months without a major overhaul.

Build your own complete waste treatment system

It is easy to build your own complete waste treatment system with a decanter centrifuge and buffer tanks both before and after. This makes sure that the unit is fed continuously and that you always have water available for your drill operation.

If you need support, Alfa Laval can assist you during the system design process and make sure that every detail is covered. Please fill in your contact details further down the page or contact one of our local offices for more information.

How it works - decanter

The rotating assembly is supported on a compact welded box beam frame with main bearings at both ends. The in-line main motor is flange- or foot mounted onto the unit with adjustable brackets for belt tension adjustment. The bowl is driven at the conical end by an electric motor with a V-belt transmission. The bowl, conveyor, casing, inlet tube, outlets and other parts in contact with the process media are made of AISI 316 or duplex stainless steel with tungsten carbide inserts in the areas most susceptible to wear.

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed enters the bowl through a stationary inlet tube and is accelerated smoothly by an inlet rotor. Centrifugal forces cause sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl. The design enables the decanter to scroll out high loads of solids without blockages caused by high levels of dryness. Only the very driest fraction of the sludge cake leaves the bowl through the solids discharge openings into the casing.

The decanter centrifuge can be adjusted to suit specific requirements by varying the bowl speed, the conveying speed, the pond depth and the feed rate

The LYNX drilling decanter

Alfa Laval LYNX centrifugal decanter systems are made for muck handling. They efficiently remove solid particles from water and oil-based slurries resulting in better penetration rates, shorter drill times, less wear on key components as well as longer sludge service life. It also reduces chemical usage as well as drill waste, which contributes to lower disposal and waste water treatment costs.

Normally installed in a bypass system, our LYNX centrifugal decanters operate continuously without interrupting drilling operations. The range can handle muck flow rates from 5 m3/hour up to 100 m3/hour. The variable bowl speed ensures the right G force required for the most efficient separation while the conveying speed can be adjusted for optimal balance between liquid clarity and solids dryness. The adjustable pond depth also contributes to the best balance between clarity and dryness.

Product information LYNX

Safety and sustainability in mining – From exploration to tailings dewatering

Alfa Laval’s solid bowl centrifuges are suitable for mining duties, from exploration to mine tailings dewatering. They enable water reuse while allowing dry disposal of tailings solids. They offer significant lifecycle cost savings and make tailings management a safer and sustainable way of working compared to tailings ponds.