Alfa Laval PureBallast 3 is ready for revised G8 – and the years ahead

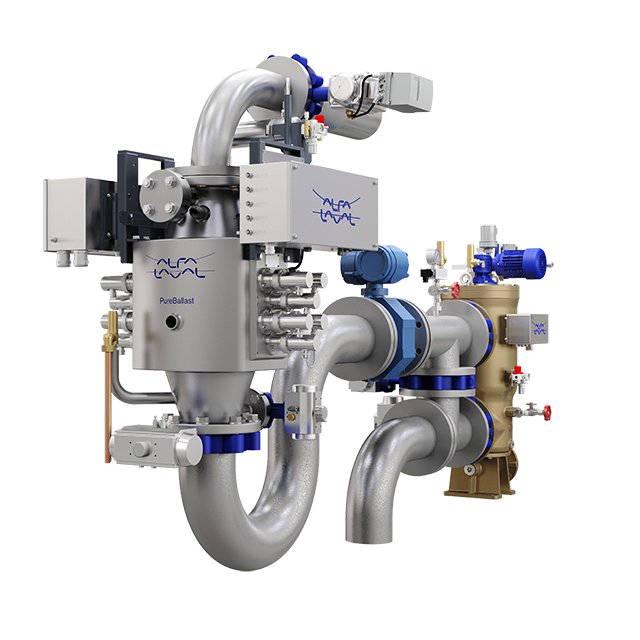

In early February, Alfa Laval PureBallast 3 became the first ballast water treatment solution to be type approved according to the revised G8 guidelines. This continues the momentum from 2017, an eventful year not only for PureBallast, but for ballast water treatment as a whole.

DATE 2023-11-27

The recent months have been important ones for Alfa Laval PureBallast 3. The third generation of the market’s leading ballast water treatment technology is now the first solution with IMO type approval according to the revised 2016 G8 guidelines. Based on tests conducted in Q3 2017, DNV GL issued the type approval certificate on behalf of the Norwegian Maritime Authority on 2 February.

“Our customers require future-proof solutions, which is why certification in compliance with the revised G8 guidelines has been a high priority for Alfa Laval,” says Anders Lindmark, head of Alfa Laval PureBallast. “Being revised G8 ready, in addition to having U.S. Coast Guard type approval, shows that PureBallast 3 is a robust solution, prepared for tough conditions worldwide.”

Momentum from PureBallast 3 Compact Flex

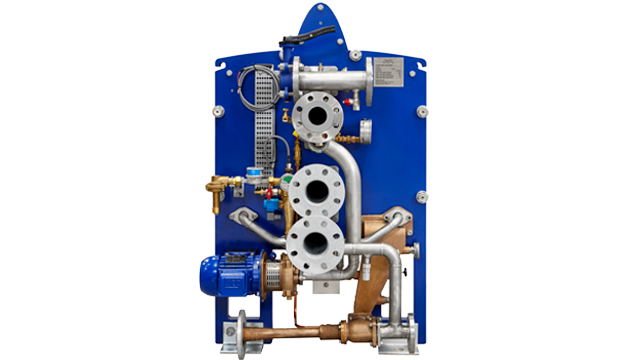

The news that PureBallast 3 is revised G8 ready follows the positive reception of PureBallast 3 Compact Flex, which was launched at the end of 2017. Based on loose components, PureBallast 3 Compact Flex packs the leading ballast water treatment technology into a footprint up to 20% smaller – and reduces installation costs by up to 10% through its plug-and-play concept.

“PureBallast 3 Compact Flex was greeted enthusiastically by customers and engineering companies, which made the launch a highlight of 2017,” says Lindmark. “Going forward, the system is also a key part of our retrofit strategy. Over the course of many retrofit projects, we’ve learned how important it is to minimize footprint and simplify installation. So those things were front and centre in the new system’s development.”

Going forward with certainty in 2018

Needless to say, the launch of PureBallast 3 Compact Flex was not the only major event in ballast water treatment last year. After years of discussion, the IMO Ballast Water Management Convention entered into force, and MEPC 71 set the implementation timetable for existing vessels. Moreover, the U.S. Coast Guard issued important clarifications about what happens if a ballast water treatment system changes hands – or the supplier disappears.

“What’s important about all these things is that the market now has answers,” Lindmark says. “We know what applies, and that knowledge is important for all players on the market. With the uncertainty gone, we can all focus on moving forward and planning properly for successful retrofit projects.”

Urgent to begin retrofit planning

In fact, many customers have already decided on their ballast water treatment systems and have retrofits in the pipeline. Others are well on their way.

“We’re starting to see a higher level of activity in the market,” says Lindmark. “That poses a risk for customers who have yet to choose a supplier or begin planning their retrofits. If they wait until the end of the year to start, they risk tighter projects that may ultimately be less successful.”

But Lindmark points out the positive as well. “Alfa Laval has been working with retrofits for a decade, so we have well-established procedures in place,” he says. “When you run a project well, including the design and engineering, you can win a lot by the time it comes to the actual installation.”

An even stronger PureBallast network

As well as building up knowledge and procedures for the coming retrofit period, Alfa Laval has invested heavily in the personnel who work with ballast water treatment. Headcount was added during 2017 to support shipyards and commissioning, and the service resources for PureBallast continue to grow.

“We’ve trained even more of our 500 field service engineers to work with PureBallast specifically, and we’ve added dedicated PureBallast engineers to cover individual regions,” says Lindmark. “Having a strong service network in place is vital, because this is a cooperation with our customers for the vessel lifetime.”

Lindmark concludes: “It comes down to customers’ compliance. Alfa Laval will be there, ready to secure and maximize their uptime.”

Other articles

Tags

All