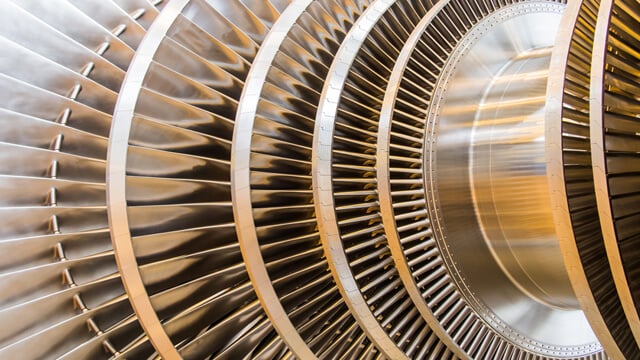

Steam turbine condensing

To improve plant economics , high thermal efficiency, minimal footprint and low maintenance are essential requirements for efficient cooling of exhaust steam from the turbine. With vast expertise in supply the power industry, Alfa Laval offers a broad portfolio of compact and reliable condensers for use in converting exhaust steam into condensate.

Steam turbine condensing

Steam turbine performance depends on how efficiently exhaust steam is condensed. By lowering the pressure after the turbine to subatmospheric levels, more energy can be extracted, resulting in higher electrical output. Alfa Laval provides condensers for both water-cooled and air-cooled duties.

The AlfaCond semi-welded plate condenser is designed specifically for plants up to 20 MW. Its plate pattern and steam distribution ensure efficient heat transfer and reliable removal of non-condensable gases. AlfaCond can be installed as a single unit or as a complete module that includes all required piping, controls and auxiliary equipment.

For evaporative cooling in closed loops, the Wet Surface Air Cooler (WSAC®) offers a compact solution. This technology provides high performance in demanding environments, ensuring stable condensing with a smaller footprint than traditional shell-and-tube systems.

Closed-loop cooling water system

A closed-loop cooling system ensures that cooling water is clean, controlled and reliable, which directly protects the condenser from fouling and performance loss. Alfa Laval supplies large plate heat exchangers that are compact, flexible and easy to adapt if capacity or process conditions change.

Since the cooling water is recirculated in a closed loop, make-up water demand and chemical treatment are reduced. This results in less pumping, fewer interventions and lower operating cost compared with open cooling towers. To maintain water quality, ALF self-cleaning filters are installed upstream of the heat exchanger.

These filters remove particles, sand and biological matter without interrupting operation. The combination of plate heat exchanger and ALF filter extends equipment lifetime and minimises maintenance, even in industrial environments.