Inorganic chemicals

Rising costs, strict regulations and global competition are shaping inorganic chemical manufacturing today. Alfa Laval’s expertise and equipment deliver cost-savings, compliance and competitive edge. For outstanding results, count on our reliable, efficient solutions for heat transfer, separation, condensation and evaporation. These boost productivity while reducing costs, energy use and environmental impact.

Optimizing inorganic chemical manufacturing

Producing inorganic chemicals – from sulphuric acid, hydrochloric acid and hydrogen peroxide to soda ash, caustic soda and fertilizers – is vital to the global economy.

To maximize inorganic chemical production processes, you can depend on Alfa Laval. With vast expertise and a broad range of equipment and services, Alfa Laval consistently handles the toughest of jobs – reliably, energy-efficiently and cost-effectively.

Whether working directly with Alfa Laval or one of our authorized partners, you are assured of the most innovative and efficient inorganic chemical manufacturing systems. Thanks to our global service network with service centres located strategically close to our customers, Alfa Laval service engineers and our long-lasting high-quality spare parts are always close at hand, wherever in the world you happen to be.

Improving energy efficiency of hydrogen peroxide production processes

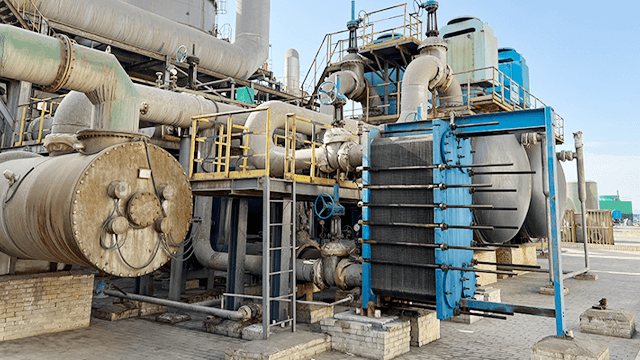

Alfa Laval leverages extensive process expertise and a diverse range of compact heat exchangers to meet the demands for efficient use of raw materials and energy in hydrogen peroxide production. Specially designed plates ensure high thermal efficiency and strong turbulence, outperforming conventional shell-and-tube heat exchangers while occupying less floor space, thus reducing operating and energy costs.

Alfa Laval also offers gasket-free solutions suitable for demanding applications such as pre-cooling oxidizer feed or cooling offgases. These solutions are highly suitable for handling corrosive fluids, featuring a compact and efficient design that saves space and lowers costs.

Exceptional corrosion resistance for large-scale hydrochloric acid production

Alfa Laval Diabon® graphite plate heat exchangers, developed in collaboration with SGL Group, combine advanced heat transfer technology with outstanding resistance to aggressive media. Their compact design offers higher thermal efficiency and requires less floor space than graphite block or conventional shell-and-tube exchangers.

Special corrugated plate patterns enhance turbulence, maximizing heat transfer and uptime. Alfa Laval provides the expertise and solutions needed for processes such as vapor condensation and acid cooling, helping reduce costs and boost yields across various industrial applications.