Chemical API processing

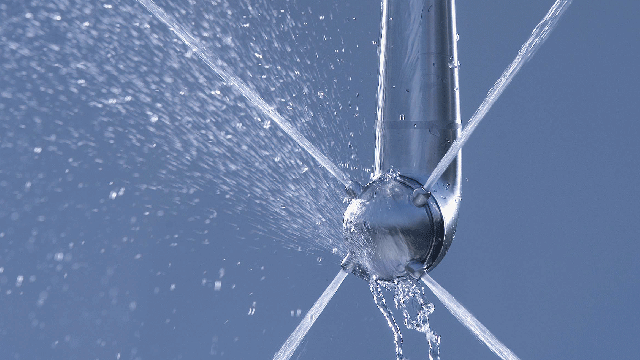

Process efficiency is key to successful production of chemical active pharmaceutical ingredients (APIs) from complex chemical substances. Increasingly, drug companies look to Alfa Laval as a turnkey supplier of process expertise, hygienic equipment and services for the manufacture of high quality chemical APIs used in finished pharmaceutical products. Equipment from Alfa Laval meets regulatory requirements, supports product stability, lowers manufacturing costs and increases production yields.

The key Alfa Laval benefits:

- Ensuring compliance with all relevant standards and cGMP

- Providing in-batch and batch-to-batch consistency

- Safeguarding product characteristics and quality

- Boosting uptime and production yields

- Facilitating commissioning, qualification, cleaning and service

Production of chemical APIs

Manufacturing chemical active pharmaceutical ingredients (APIs) poses distinct challenges because APIs sometimes require a unique set of processes to obtain the final product. Successful manufacturing therefore requires process efficiency to produce stable APIs in a safe, consistent and cost-effective manner, while preserving the safety, identity, strength, quality and purity of the API.

As a knowledgeable expert partner to pharmaceutical manufacturers, Alfa Laval has a broad range of hygienic equipment that deliver at every stage of the chemical API production, whether it’s measuring, pumping, separating, diverting, heating, cooling, agitating, mixing, automating, controlling or cleaning for critical processes. Through process optimization, Alfa Laval helps customers lower costs, increase uptime, minimize contamination risks, and safeguard the purity and maximize the yield of produced APIs.

All components are supplied with comprehensive pharmaceutical documentation packages based on Good Documentation Practice (GDP). For Alfa Laval UltraPure pumps, valves, tank equipment and heat exchangers we have the Alfa Laval Q-doc package which ensures full traceability of all process contact parts of the equipment supplied.

Case stories