Flexitherm Core

Alfa Laval Flexitherm Core is a range of standardized pasteurization modules for pasteurization of beer and other beverages. Flexitherm pasteurization technology is widely considered the solution of choice to assure long shelf life for hygienically packed perishable beverages (carbonated or not). All modules are pre-engineered with mainstream process design configurations and automation setups that are an ideal match for pre-defined sets of operating conditions.

Stable product treatment even during variable flow

- Consistent pasteurization due to reliable control of pasteurization units (variations within +/- 10% of target assuming constant operating condition

- Sustainable operation with very low energy consumption (effective energy recovery up to 94%)

- Standardized plug-in design ensures quick, on-time delivery (ready to ship 12 weeks after finalized order)

- Minimum of on-site installation and commissioning (as little as 2 weeks) with pre-assembly and factory testing of the frame-mounted module

- Exceptional production efficiency and minimal product losses with state-of-the-art automated control system that precludes operator intervention

Machinery for the vast majority of pasteurization requirements

The standard configurations in the Flexitherm Core range cover the majority of normal pasteurization capacity requirements (40 to 400 hl/hr) for pasteurization of beer and other beverages. Each pasteurization module is optimized to deliver a constant pasteurization effect (selectable from 10–100 units) at variable flow, based on following:

- Product inlet/outlet temperature of 2°C and pressure of 200 kPa

- CO2 content up to 6.0 g/litre

- Pasteurization temperature 67–76°C

- Holding time of 30 secs at maximum capacity

How it works

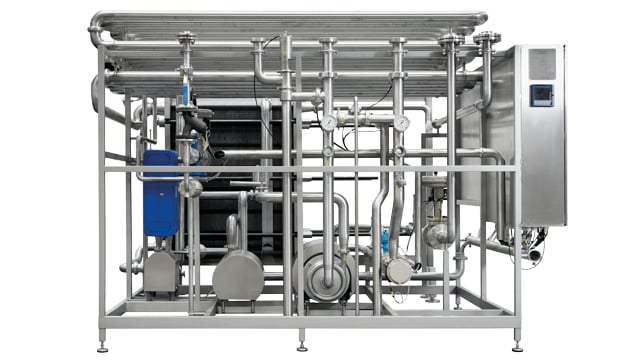

Pasteurization module design

The modular design of the Flexitherm Core pasteurization module has two distinct parts:

- thermal processing equipment

- buffer tank and routing

A comprehensive selection of standardized, tried-and-tested configurations is available.

Thermal processing with high heating recovery and flexible capacity

The thermal processing equipment lies at the heart of the Flexitherm Core pasteurization module. Here the incoming product is heated, treated and cooled. Product heating takes place first in the heat recovery section, which keeps energy consumption to a minimum, then in a dedicated heating section to achieve the required pasteurization temperature. To minimize product degradation from over-exposure to high temperature, the heating section re-circulates water through a brazed plate heat exchanger that is fed with steam. To reach the required outlet temperature, the treated product is first cooled in the heat recovery section, then in a dedicated cooling section using an external cooling media. Where there is unstable cooling media supply, an optional recirculation pump ensures consistent and optimal cooling conditions and prevents the product from freezing inside the heat exchanger.

The capacity of the thermal processing equipment can be adjusted to accommodate variations in demand during the filling process, with the pasteurization temperature automatically adjusted to maintain a consistent pasteurization unit effect at all times.

Optional features for the thermal processing equipment include control of the inlet pressure, automatic media shut-off valves, steam pressure regulation, condensate recovery, among others.

Well-structured PLC software in the pasteurization modules ensures straightforward integration of the automated control system into a larger-scale monitoring system via Ethernet or Profibus.