M line

Alfa Laval M line of gasketed plate-and-frame heat exchangers is used for high design pressure (>10 bar/145 psi), such as in carbonated beverages. The large range of plate and gasket types complies with Food Contact Materials (FCM) requirements for pasteurization and other heating and cooling duties in hygienic and utility applications in the dairy, food, beverage and pharmaceutical industries.

Heat exchangers for high pressure hygienic processes and utility applications

- Engineered specifically for high design pressure

- High degree of service-friendliness – FDA compliant gaskets for easy opening, inspection and cleaning, and also designed for Cleaning-in-Place(CIP)

- Fouling resistance and thermal efficiency thanks to range of pressing depths and chevron patterns as well as various corrugations

- Flexible – heat transfer area can be modified by adding or removing plates or combining different plates and material if process parameters change

- Suitable for multi-section heat exchangers for pasteurization saving on space, piping and costs

Optimization of duties: M line high pressure heat exchangers are available in three different sizes and work with various plate types to ensure optimal performance in your application

Plate types for different hygienic needs

Two different plate types are available for BaseLine & M Line gasketed plate heat exchangers:

- Chevron type plate pattern ensures good distribution of the product as well as high thermal efficiency and is used in food, dairy, beverage and pharma industries.

-

Gemini double-wall plates ensure a fully mix-proof design. It consists of two plates pressed together and prevents cross contamination between fluids in case of leakage through the plates.

The chocolate pattern distribution area ensures that the fluids are evenly distributed across the entire plate to avoid stagnant zones that can result in fouling.

The chocolate pattern distribution area ensures that the fluids are evenly distributed across the entire plate to avoid stagnant zones that can result in fouling.

How it works

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, where the counter-current flow helps attain the highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Alfa Laval hygienic liquid/liquid GPHE

Alfa Laval multi-section pasteurizer GPHE

Multi-section hygienic GPHE

Features

Adjustable feet

Bearing box

Connection plate roller

Elongated nuts

Fixed bolt head

Key hole bolt opening

Lock washer

Pressure plate roller

Tightening bolt cover

Part of a broad range of hygienic gasketed plate heat exchangers

Ten top tips - Hygienic Gasketed Plate Heat Exchangers

Here are some tips and service videos to show you how you can keep your hygienic gasketed plate heat exchangers in tip top condition.

Demand new standards

Introducing the world’s most modern gasketed plate heat exchangers. Discover how our next-generation line of gasketed plate heat exchangers will bring you higher efficiency, better reliability and greater serviceability.

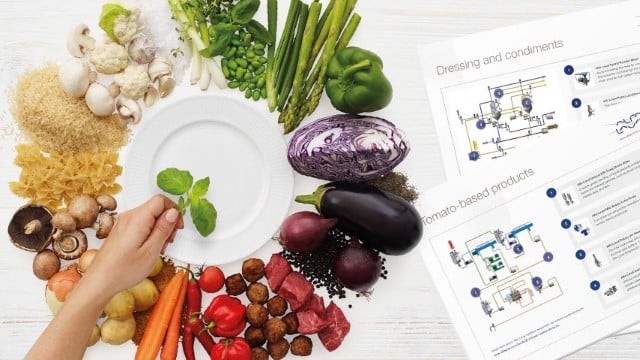

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.