Industrial semi-welded line

Semi-welded plate heat exchangers are suitable for refrigeration, chemical processes and various kinds of industrial utility duties. The unique Alfa Laval RefTight™ sealing system guarantees a long lifetime sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

Highly efficient and flexible

- Space-saving compact unit

- Low operating cost possible owing to superior energy efficiency and prolonged service intervals

- Safe and reliable sealing with no risk of cross-contamination

- Pressure and temperature fatigue resistant

Higher pressures demand a higher standard

If your heating and cooling duties demand higher pressures, it’s time for your business to demand a higher standard of technology. Discover total reliability and efficient thermal performance with the Alfa Laval range of semi-welded heat exchangers.

Highly efficient with unique sealing system

Highly efficient with unique sealing system

Alfa Laval industrial semi-welded gasketed plate heat exchangers are suitable for liquids and gases incompatible with normal gaskets or at higher pressures. Commonly used in refrigeration applications for evaporation and condensation of ammonia and CO2.

The unique Alfa Laval RefTight™ sealing system guarantees a long life-time sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

What make our plate heat exchangers so reliable, efficient and serviceable?

Equipped with well-designed features that make a difference, Alfa Laval Industrial semi-welded line of heat exchangers are easy to maintain and have a long service life.

RefTightTM sealing system

RefTightTM sealing system

High performance gasket sealing for high-pressure duties

CurveFlow™

CurveFlow™

distribution area

Improves media flow and minimizes risk of fouling.

OmegaPort™

OmegaPort™

noncircular port holes

Enhances media flow and thermal efficiency.

ClipGrip™

ClipGrip™

gasket attachment

Ensures perfect seal and trouble-free maintenance.

Five-point alignment

Five-point alignment

Ensures reliable plate positioning and easy service of large units.

T-bar roller

T-bar roller

Provides a lower unit that is easy to service.

How it works

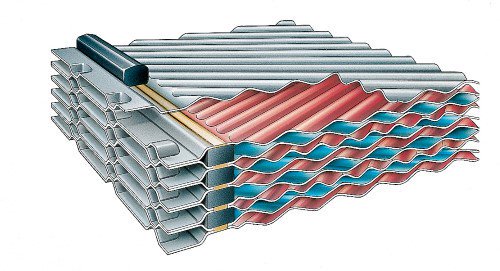

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The sealing between the plates on the Industrial semi-welded line alternates between laser welds and gaskets. The laser welded channel allows use of fluids that are not compatible with normal gaskets and also allows for higher design pressure than fully gasketed plate-and-frame heat exchangers. Additionally, the Alfa Laval RefTight™ sealing system guarantees equal sealing force over the entire porthole gasket.

Industrial semi-welded line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.