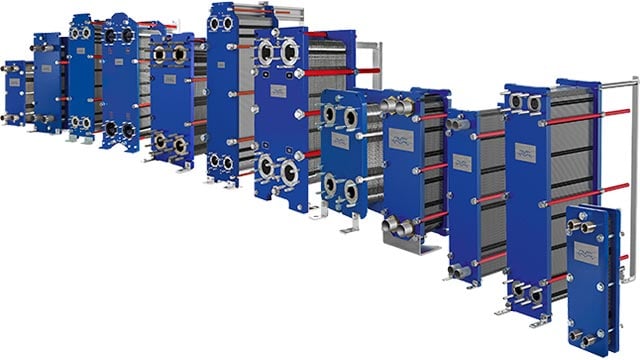

Industrial line

Our wide range of industrial gasketed plate heat exchangers is suitable for all types of industry and multiple applications from heating, cooling and heat recovery to condensation and evaporation. We are constantly looking to extend and upgrade the range, adding new performance criteria and greater flexibility. What’s termed ‘next-generation’ today will soon be standard for the entire Alfa Laval Industrial line.

Towards new standards in efficiency, reliability and serviceability

- High energy efficiency

- Flexible – configurable for broad range of applications

- Ensures optimal performance in specific applications based on specific needs

- Easy to install

- High serviceability

Are you on a quest to save energy?

Alfa Laval is setting the standard for thermal efficiency of plate heat exchangers. Bringing together innovative features improving energy efficiency and minimizing downtime we can accelerate the transition to more sustainable solutions and reach net-zero by 2050.

Do you need BIM files?

Heat exchangers from Alfa Laval are now available in the digital infrastructure for BIM objects. Preview and download building information modelling (BIM) files for your heat transfer solutions.

Save your energy – from start to finish!

Benefit from Alfa Laval’s decades of experience of working with EPC projects and your end customers. We can support you throughout the project to make sure your customers get the optimal heat exchanger package.

Demand new standards

Introducing the world’s most modern gasketed plate heat exchangers. Discover how our next-generation line of gasketed plate heat exchangers will bring you higher efficiency, better reliability and greater serviceability.

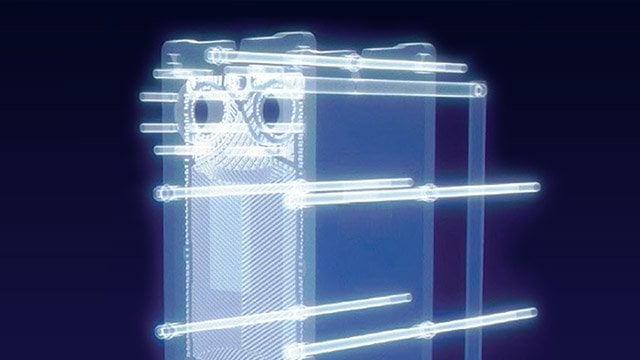

How it works

The heat transfer area of a gasketed plate heat exchanger consists of a series of corrugated plates, assembled between a frame and pressure plates to retain pressure. Gaskets act as seals between the plates. Fluids normally run counter-currently through the heat exchanger. This gives the most efficient thermal performance and enables a very close temperature approach, ie the temperature difference between the exiting process medium and the entering service medium.

Alfa Laval liquid/liquid gasketed plate-and-frame heat exchanger

Alfa Laval steam heater gasketed plate-and-frame heat exchanger

Alfa Laval 2-pass gasketed plate-and-frame heat exchanger

Features that make the difference

The Industrial line is equipped with features that turn this high-performance family into efficient and reliable workhorses that are easy to service and maintain over the whole product lifecycle.

For efficiency

By improving the efficiency of your heat exchanger, you can maximize production and minimize energy consumption to reduce your power bill and improve your environmental footprint.

See product animations below or get more information and listen to our technical experts.

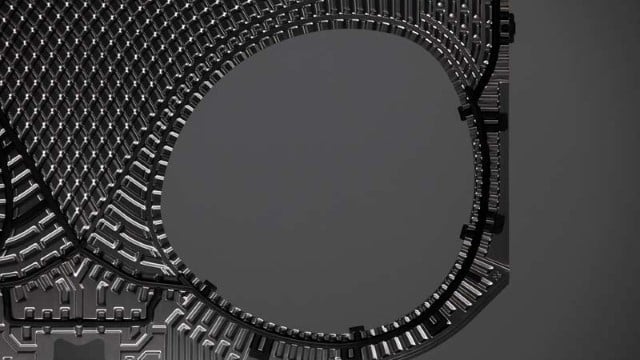

CurveFlow™

CurveFlow™

distribution area

Improves media flow and minimizes risk of fouling.

OmegaPort™

OmegaPort™

noncircular port holes

Enhances media flow and thermal efficiency.

FlexFlow™

FlexFlow™

plate design

Improves thermal efficiency and optimizes pressure drop utilization.

Offset gasket groove

Offset gasket groove

Ensures plate utilization for maximum heat transfer efficiency.

For reliability

We are always looking to increase the reliability of every aspect of our gasketed plate heat exchangers. We focus on durable designs based on robust materials and safe manufacturing processes.

See product animations below or get more information and listen to our technical experts.

PowerArc™

PowerArc™

plate pattern divider

Improves plate rigidity for longer lifetime.

Five-point alignment

Five-point alignment

Ensures reliable plate positioning and easy to service for large units.

SteerLock™

SteerLock™

plate alignment

Ensures reliable plate positioning and easy service.

For serviceability

The simple opening and closing of the plate-and-frame design with gaskets enables hassle-free inspection and service. It also enables you to easily adapt the unit to new process conditions.

See product animations below or get more information and listen to our technical experts.

ClipGrip™

ClipGrip™

gasket attachment

Ensures perfect seal and trouble-free maintenance.

T-bar roller

T-bar roller

Provides a lower unit that is easy to service.

Bearing boxes

Bearing boxes

Guarantees an easy-to-open unit for smoother, more efficient maintenance.

Compact frame

Compact frame

Facilitates maintenance and minimizes service area requirement.

Discover more features

There are many more features in an Alfa Laval gasketed heat exchanger that make a difference. New innovations and proven concepts together offer extensive benefits such as low total product life cycle cost, increased production output, minimized downtime and increased staff safety.

See the product leaflets to find the full list of features of each model in the Industrial range.

Corner guiding

Tilted bolt opening

Leak chamber

Elongated nuts

Lock washer

Fixed bolt head

Key hole bolt opening

Pressure plate roller

Different plates for different industrial needs

Plates are available with various pressing depths, angles of chevron pattern and various corrugation shapes, which are all carefully designed and selected to achieve optimal performance. Our Industrial line is available with four main plate configurations:

- Single plate with chevron pattern for parallel flow for optimum thermal performance and pressure drop.

- Single plate with chevron pattern for diagonal flow for optimum thermal performance when mounted horizontally and complete drainability is required.

- Double-wall plate when you need to avoid mixing fluids.

- Gemini double-wall plate when you need to avoid mixing fluids in hygienic applications.

The distribution area ensures that fluids are evenly distributed to the heat transfer area and helps avoid stagnant zones that may cause fouling.

There are a number of design features that help maximize heat transfer. The high efficiency per m2 minimizes the number of plates and the raw material used. This results in a compact, space-saving unit.

While high flow turbulence between plates results in higher heat transfer, the consequence is pressure drop. Our thermal design engineers can help you select the model and configure to what is suitable for your application so that it delivers maximum thermal performance with minimum pressure drop.

Gasket profile

Gasket glue

The gaskets are used to efficiently seal the heat exchanger. The gasket profile, width, thickness, type and compound of polymer are configured to each heat exchanger and its intended duty. Depending on application and frequency of unit openings, the gasket is either fastened by its clips or fingers or glued to the plate. We use a specially developed two-component cured epoxy glue for maximum adhesion in applications where frequent cleaning is necessary.

AHRI certified industrial gasketed plate heat exchangers

The Alfa Laval AlfaQ range of heat exchangers are certified according to the AHRI* Liquid to Liquid Heat Exchangers (LLHE) Certification Program (AHRI 400) which ensures thermal performance according to a manufacturer's published specifications. Typical HVAC applications include district cooling substations, ice-storage systems, data centre cooling and free cooling systems. To read more about the Alfa Laval AlfaQ range.

- Eliminate uncertainty about thermal performance

- Reduced system-wide energy use and operating costs

- Uncompromised environmental performance

- Independent assurance

- Three-year warranty

Under-dimensioned heat exchangers can lead to higher system-wide energy use, higher operating costs and compromised environmental performance. With AHRI certification, you are assured that the plate heat exchanger will function as required. No risk of underperformance. No uncertainty. It does what it says on the box, guaranteed.

*The US Air conditioning, Heating & Refrigeration Institute (AHRI) certification is the only global, third-party performance certification for plate heat exchangers.