Tank cleaning upgrade cuts water consumption by 17%

In light of increasing pressures on freshwater resources, a leading US based brewery group has committed to increasing water efficiency and cutting water consumption in its operations. One of the water-saving measures focused on optimizing the tank cleaning process. The installation of new rotary jet heads from Alfa Laval reduced water consumption for tank cleaning by as much as 17%.

DATE 2024-04-26Look to tank cleaning for substantial water savings

Water is the number 1 ingredient in beer, consuming millions of liters of clean freshwater every day. In response to the increasing water challenge, a leading American brewery group has set out to reduce water consumption in its operations. One of the obvious places to look for water savings is in the water-intensive tank cleaning process. The brewery uses large fermentation tanks where active yeast converts sugars into alcohol. The size and horizontal layout of these tanks present a special challenge in the cleaning process and calls for advanced technology to ensure proper cleaning of all surfaces between brewing cycles.

Upgrade of jet heads saved massive amounts of water

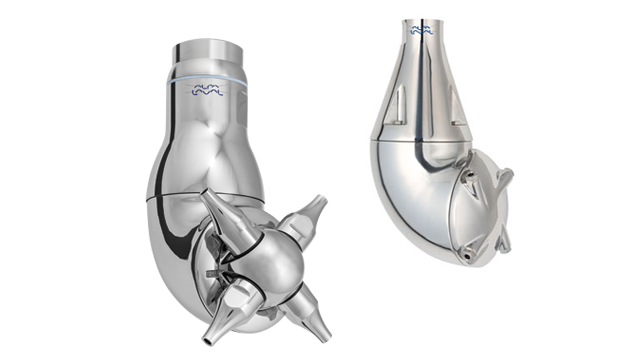

Inspired by a similar project in China, the brewery group decided to upgrade the original Alfa Laval GJ 4 units with new TJ40G rotary jet head units. The TJ40G uses less water than the GJ 4 and completes the full cleaning pattern faster. The lower water usage combined with the faster cleaning time saves roughly 760 litres (200 gallons) during the final rinse and sanitizing steps. After the first months of operation, the new TJ40Gs have proved to return water savings of 17%. The total water savings for the fermentation tanks are estimated to be around 5.7 million litres per year (1.5 million gallons).

“We have worked with the leading American brewery group for more than 30 years, and we are pleased that we can now help the customer reduce the operating costs and at the same time achieve their sustainability goals by increasing the water efficiency in the tank cleaning process. As a valuable side effect, the reduced water consumption also drives savings in chemicals and energy used for pumping, heating, recovery, re-use, and treatment of cleaning water”, says Andrew Delaney, General Manager Tank Cleaning at Alfa Laval US.

Plug and play installation

The old and the new jet heads use the same inlet connections. The installation time was less than one hour per tank, comprising three jet heads per tank. The replacement of jet heads took place in between fermentation cycles and caused no extra downtime in the process. The free rotation and the integral ball bearings of the TJ40G extend the maintenance intervals by 50% compared to the older GJ 4 units. The positive results of the first installation of new jet heads pave the way for further updates of the tank cleaning equipment at the brewery’s other locations across the US.

Innovation highlight

Download the case story

Facts about the upgrade project

Alfa Laval TJ40G Rotary Jet Head units are designed for hygienic applications and provides automated cleaning of vessels between 50 and 500 cubic metres liquid (13,000 and 132,000 gallons). The design of the advanced jet heads is optimized for cleaning of brewing tanks and for food and dairy processes. TJ40G is FDA approved. The upgrade of tank cleaning equipment is part of Optimize™ by Alfa Laval, which aims to enhance the water and energy efficiency of hygienic industries.

The water savings correspond to estimated CO2e savings of more than 100 tonnes

5.7 million litres (1.5 million gallons) of water saved per year

Tags

All