Biogas production

As demand rises for biogas and biomethane, their potential in combating greenhouse gas emissions is crucial. According to the IEA, the biogas market is expected to grow with an annual growth rate of 11%. At Alfa Laval, we value the circular economy, transforming organic feedstock and waste into valuable energy resources. Our separation and heat transfer technology supports waste-to-biogas processes for optimal results, including pre-treatment, digestion, and post-treatment stages .

Accelerating growth of biogas production

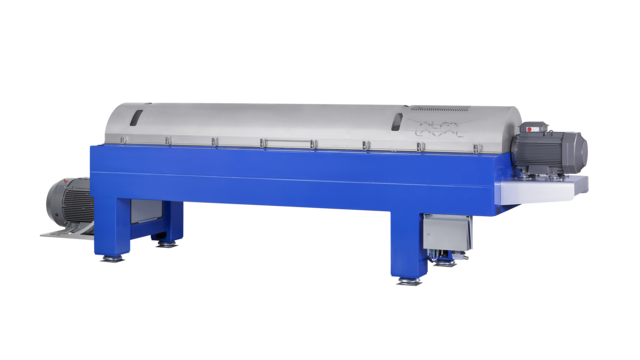

- Low energy consumption with ALDEC decanter centrifuges and drum thickeners

- Quick and low-cost installation with Alfa Laval drum thickeners, decanter centrifuges and spiral heat exchangers

- Skid is available for the oil separation process in anaerobic digestion

- Superior heat-transfer and maximum operating efficiency with spiral heat exchangers

- Access to Alfa Laval process knowhow and global network of service

Partner with Alfa Laval

Alfa Laval experts can help biogas operators improve resource efficiency and reduce, reuse, and recycle waste so that you optimize your production processes and achieve more sustainable results. Whether it’s the establishment of new biogas plants or the expansion of existing ones, our expertise in heat transfer and separation technologies, along with a global service and support network, enables quick and efficient set up.

Partnering with Alfa Laval also means you get access to our global presence and network as we take care of the lifecycle of your critical heat transfer and separation equipment.

"Alfa Laval’s spiral heat exchangers are vital equipment for stable operation of our digester and overall plant economy as it saves a lot of money through heat recovery," - Lars Albak Kristensen, Plant Manager, Lemvig Biogas Plant

AGSM (Azienda Generale dei Servizi Municipalizzati) in Verona, Italy, uses an ALDRUM MegaDuo to thicken solid waste from 5% to 13% DS without using polymers. The sludge is then transferred to an anaerobic digester to produce biogas.

Pre-treatment

When treating municipal solid waste in a wet system before anaerobic digestion, several steps take place, including milling, magnetic separation, pulping, inert separation, thickening, and hygienization. Thickening the pulp using Alfa Laval drum thickeners and decanter centrifuges offers benefits such as reducing the load on downstream processes, lowering energy consumption, and increasing biogas yield. The water from the pulp can also be recycled. Regulations often require hygienization and can be achieved through pasteurization using efficient spiral heat exchangers, which help maintain stable anaerobic digestion by controlling the sludge temperature closely.

Anaerobic digestion

Anaerobic digestion is a crucial stage in which microorganisms break down the pulp without oxygen, producing methane and carbon dioxide gas. Prior stages aim to optimize the digestion process by increasing dry solids feed, controlling temperature, and enhancing capacity and biogas yield. In the post-digestion stage, effective dewatering and nutrient recovery are essential, which Alfa Laval achieves through high-performance decanter centrifuges. Spiral heat exchangers can also be used for post-digestion hygienization, offering benefits similar to those in the pre-treatment stages.

Oil separation in anaerobic digestion for a diversified revenue stream

Oil separation in anaerobic digestion for a diversified revenue stream

Alfa Laval is working with AD operators globally, placing the Prodec Oil Plus decanter centrifuge between the acidogenesis and acetogenesis stages of anaerobic digestion, creating ideal conditions for oil separation. The innovative decanter centrifuge near the pasteurizer allows for slurry separation without impacting the overall process. The unique operation of the decanter prevents solids from compacting within the chamber, ensuring that all oil introduced into the machine can be fully recovered.

Case story: BioteCH4

A UK-based waste-management company uses cutting-edge decanter separation technology to tap into a brand-new revenue stream – turning waste oils and fats into high-quality feedstock for the biofuel industry.

Service

Our global service network has dedicated specialists, knowledgeable about your industry. We are here to support you with parts and expertise, wherever and whenever you need them.

The Alfa Laval 360° Service Portfolio covers all your needs throughout the life cycle of your equipment — from start-up, maintenance, support and improvements to monitoring services — for maximum uptime, availability and optimization.

By minimizing your total cost of ownership, we help you stay ahead of the competition.