Replacement and Retrofit

When it's time to replace your equipment

Sooner or later servicing your centrifuge or plate heat exchanger just isn't enough. But how do you know when it’s time to move from fixing it, to replacing it? Whether you’re looking to be more efficient, increase yield, or your equipment is not as reliable as it once was, let Alfa Laval help you navigate to a better solution.

Our approach

Our approach is consultative – we are here to help you and identify where your product is in its lifecycle, and we’re ready to provide a replacement recommendation, based on your budget and application needs. And if you haven’t recently replaced your equipment, a lot has changed. We’ll guide you through the latest technologies, and how they might enhance your production process.

Are you on a planned asset renewal cycle?

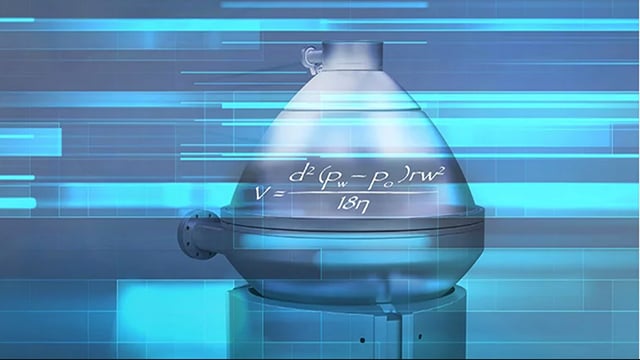

Whether you’re a Municipality, Food or Industrial facility, your centrifuge is likely on a longer-term replacement schedule. Maybe its time to look deeper into Alfa Laval, and our range of sustainable solutions. One example is decanter centrifuge VecFlow – which cuts energy consumption by 30% or more. Ultimately, we will provide solutions that improve reliability, reduce operating cost, increase uptime, yield, and production – reducing your overall carbon footprint. And, if your process could use a technology upgrade, we can provide immediate solutions that increase production.

Do aging equipment issues point to a developing need?

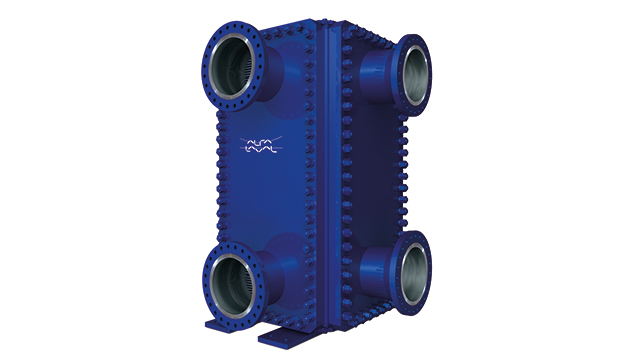

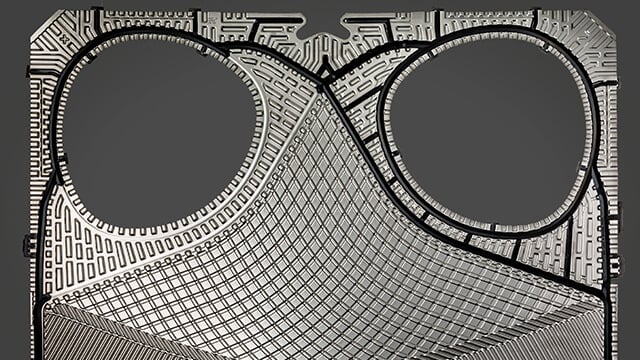

Maybe your plate and frame heat exchanger is running well, but you are contemplating upgrading to the benefits of our latest technology? Alfa Laval can help identify how a new equipment alternative might save you money now, and pay for itself in the future. Many of our latest products, like a hermetic eDrive centrifugal separator, are designed to increase your capacity or improve your production yield. We can also show how our new GPHE T-Series plates increase energy efficiency, and reduce your overall carbon footprint.

Is your equipment at risk of causing a crisis?

So, you didn’t plan on purchasing a new Alfa Laval heat exchanger just yet, but production demands require an immediate solution? We have customer support; engineering; and service teams available – to help right now with immediate options to keep you operating until new equipment can be procured and installed.

Physical signs of replacement:

- Additional operating noise or vibration

- Increased leaks or product loss

- Reduced end-product quality

- Equipment deterioration

Operational issues that point to replacement:

- Product no longer meets code or industry certifications

- Requires more frequent cleaning, maintenance and downtime

- Unable to find Genuine replacement parts

- Not as energy efficient

- No longer meets plant’s sustainability requirements

- Doesn’t sync with latest plant automation

- Existing equipment doesn’t fit new revenue stream

- Power savings (costing a lot to run)

- Carbon footprint reduction

- Longer than normal maintenance downtime

- Process yield reductions

Our product areas of expertise

Disc stack centrifuge

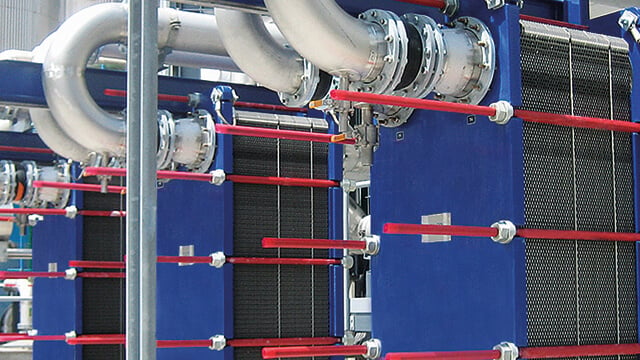

Gasketed plate heat exchangers

Decanter centrifuge

Welded spiral heat exchangers

Welded plate-and-block heat exchangers

Latest innovations

Separator innovator

GPHE Branded features

ConditionAlert